Ring gauge | 40mm ring gauge-accuracy DIN 2250

Precision vice AVK-160 mechanical with mechanical booster

Ausfuhrung:

- Mit mechanischem Spannkraftverstarker

- Spannkraft voreinstellbar durch Rillenmarkierung

- Horizontal und vertikal aufspannbar

- Stahlkorper allseitig geschliffen und gehartet

- Eingebauter Niederzug

- Betthohe H: 0,01 mm

Delivery:

- Instructions for use

- Wrench

- 4 pcs. vice clamps

- 4 pcs. T-nuts 18 mm

- Test certificate

End mill holder Weldon with cooling channels SK 40 – 18 – 63

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw and O-ring

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

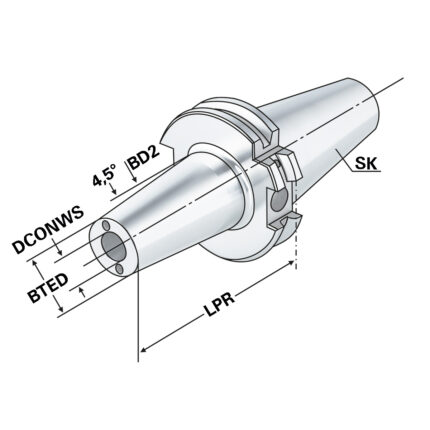

Shrink chuck 4,5° with cooling channels SK 40 – 12 – 80

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance2

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Combi shell mill holder MK 5 – 32 – 75

3D-Taster analog 12mm Schaft

Der 3D-Taster besticht durch sein schlankes und attraktives Design. Seine prazisen und vielseitigen Einsatzmoglichkeiten erlauben schnelles und einfaches Ermitteln von Werkstucknullpunkten und Langenma?en.

Die Antastung ist in allen Achs-Richtungen (X/Y/Z) bei gleicher Zeigerauflosung moglich.

Sobald die Zeiger 0" anzeigen, steht die Spindelachse prazise auf der Werkstuckkante.

Der Schutz der Messeinheit steht im Vordergrund. Hierzu wurden gro?e Uberfahrwege in die Tasteinheit integriert. Diese sind durch mechanische Endanschlage begrenzt. Der Tasteinsatz hat eine Sollbruchstelle, die ganz weit oben angebracht ist. Sollte Ihr 3D-Taster durch au?ere Krafteinwirkung trotzdem beschadigt werden, so ist eine einfache Reparatur kostengunstig moglich.

Hinweis:

- not waterproof

- without test certificate

- without serial number

Shell mill holder HSK 100 – 32 – 160

Application:

For mounting milling cutters with transversal groove.

Note:

d = 40/d = 60: For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant. For d = 60 only with four fi xation screws according to DIN 912.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined