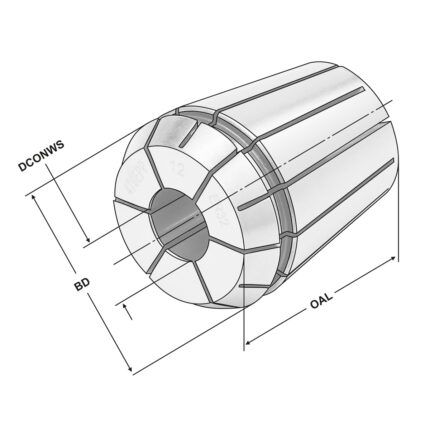

ER-Spannzange mit Kuhlkanalen ER32 | 470ECC | < 15µm | O 15

Morse taper adaptor – form F1 F1 – 16 – MK1

ER-Collet ER16 | 426E | < 15µm | O 8 - 7

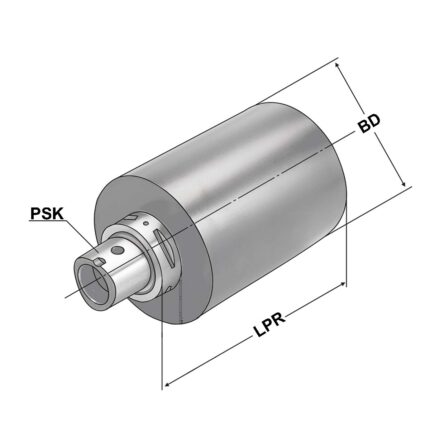

Adaptor SK to ISO 26623 (PSK) SK 40 – PSK 32 – 30

Application:

For adaption from ISO40 to PSC (ISO 7388-1 to ISO 26623-1)

Delivery:

Clamping screw

Version:

Adapters ISO / PSK with axial clamping. Ground internally and externally. The internal thread provided for the coolant tube in the PSC toolholder is plugged with the socket-head screw incorporated in the adapter. The clamping screw incorporates a through hole, so the system is suitable for through-coolant feed.

Suitable for tool arbor with polygonal shank (PSC) - ISO 26623-1.

ER-Precision collet ER32 | 470EPP | < 3 µm | O 6,0

Application:

For mounting straight-shank tools in collet chucks ISO 15488 (ex. DIN 6499).

Version:

System concentricity and repetition accuracy 3 µm (3?D, maximum = 50 mm), in conjunction with KEMMLER Precision collet chuck ER".

Suitable for:

KEMMLER Precision collet chuck ER or standard collet chuck Spannfutter ISO 15488 (ex. DIN 6499).

Note:

The collet clamping O range is always up to 0.5 mm less than nominal.

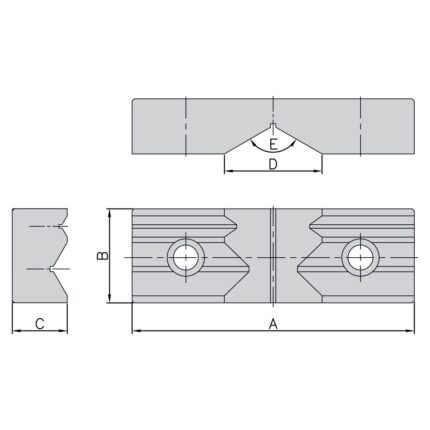

Radial toolholder – form B3 overhead right short B3 – 50 x 32 – 55

Application:

Mainly for external machining. For face machining.

Precision coolant supply: Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.With high precision coolant you get improved

chip breaking, longer tool life, better process security and productivity. Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.