PART OF CATALOG

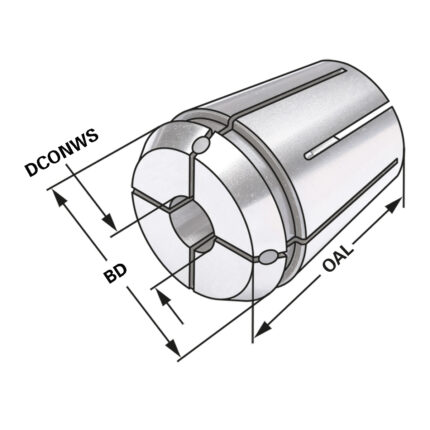

ER-Gewindebohrer-Spannzange IK ER32 | 470GA | < 15µm | 14 x 11

OZ-Collet OZ32 | 467E | < 15µm | O 26 - 25,5

Claw jaws set (Pair) for AVQ-125 | AVL-125

Version:

Jaws with grip serrations und fine step for workpieces with max. edge radius 1 mm, clamping depth 2 mm

- For use on vises

- Simple, safe clamping of parallel raw and sawn parts

- Hydraulic or manual clamping

- Positive clamping due to penetration of the hardened claw tips

- High holding forces: increase by a factor of 3 to 5 compared to standard jaws

- Low material loss

- Shortened processing times and reduction of production and unit costs

Clamping sleeves for taps with quick change DCONMS=25 | 12 x 9

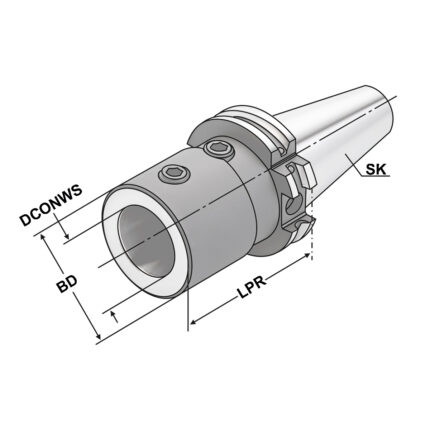

Hydraulic expansion chuck BT 30 – 10 – 64

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Delivery:

With wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Boring holder for drills with indexable inserts | SK 40 – 32 – 75

Application:

For mounting solid drills with cylindrical shank according to DIN 6595.

Note:

Contact surface precision grinded

Delivery:

With clamping screws

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

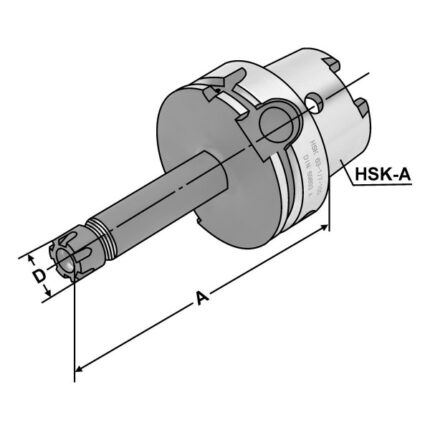

ER-Collet chuck HSK 63 – 2/16 – 100 | ER 25 | Mini

Application:

For mounting straight-shank tools in collets.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

FREE CONSULTATION