PART OF CATALOG

End mill holder Weldon HSK 50 – 25 – 110

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Shrink chuck 3° SK 40 – 10 – 160

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

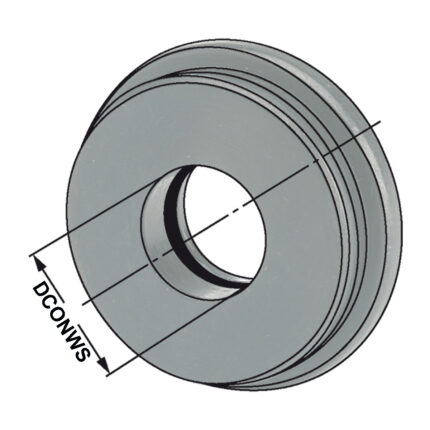

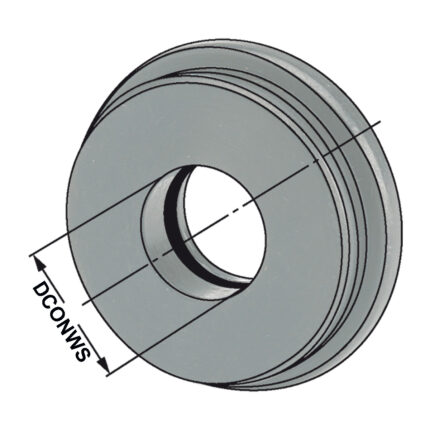

Sealing disc | ER 25 DCONWS = 3,5

Sealing disc | OZ 16 DCONWS = 13,0

OZ-Collet chuck SK 30 – 2/25 – 80 | OZ 25

Application:

For mounting straight-shank tools in collets.

Delivery:

With ball bearing clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

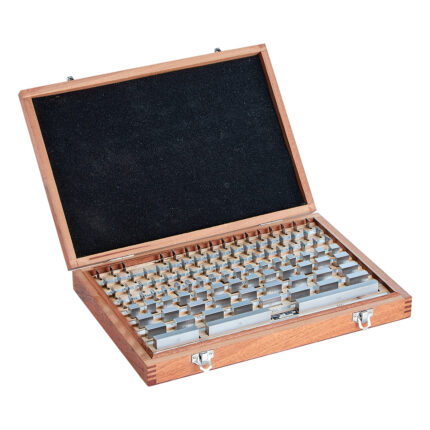

Rectangular gauge block set | 87 pieces Grade 2 | (ISO / DIN / JIS /GB)

FREE CONSULTATION