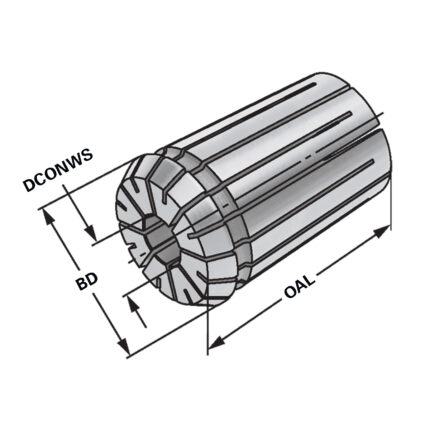

ER-Collet with cooling channel holes ER25 | 430EC | < 15µm | O 14

OZ-Collet OZ25 | 462E | < 15µm | O 8 - 7,5

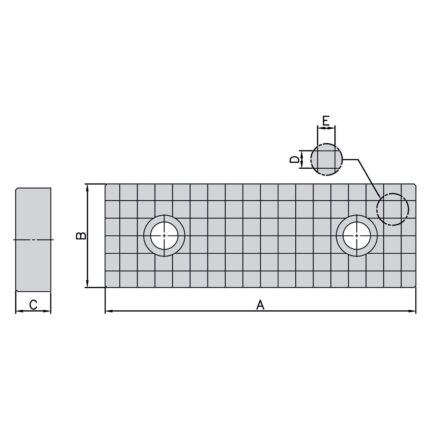

Shell mill holder SK 40 – 27 – 40

Application:

For mounting milling cutters with transversal groove.

Note:

d = 40/d = 60: For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant. For d = 60 only with four fi xation screws according to DIN 912.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Precision collet set | radial run-out of < 3 µm ER 32 | 470 EHP | 15-part kit in wooden box

Application:

Metallic sealed for mounting straight-shank tools with coolant-through in collet chucks ISO 15488 (ex. DIN 6499).

Version:

Metallic sealed Collets for internal cooling (applicable up to 100 bar).

System concentricity and repetition accuracy 3 µm (3?D, maximum = 50 mm), in conjunction with KEMMLER Precision collet chuck ER".

Suitable for:

KEMMLER Precision collet chuck ER or standard collet chuck Spannfutter ISO 15488 (ex. DIN 6499).

Note:

Clamping range h6 (nominal size only).

Metallic sealed Collets for internal cooling (applicable up to 100 bar). In order to achieve an optimum sealing the tool must be clamped on the complete length of the ground drill of the collet.

3 point internal micrometer | digital 100-125mm | IP65 | reading 0,001mm

Construction:

- Graduation: 0.001mm

- Measuring contact points are designed to allow measurements near to the bottom of blind holes

- reading parts brushed chromium-plated

- Measuring surfaces are carbide

- Ratchet stop

Delivery:

- Extension

- Warranty card

- Instruction manual

- Calibration certificate

- LR44 1,5V Battery

Setting ring not included in delivery - optionally available

Axial toolholder – form C3 overhead right C3 – 50 x 32

Application:

Mainly for external machining. For face machining.

Precision coolant supply: Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.With high precision coolant you get improved

chip breaking, longer tool life, better process security and productivity. Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.