PART OF CATALOG

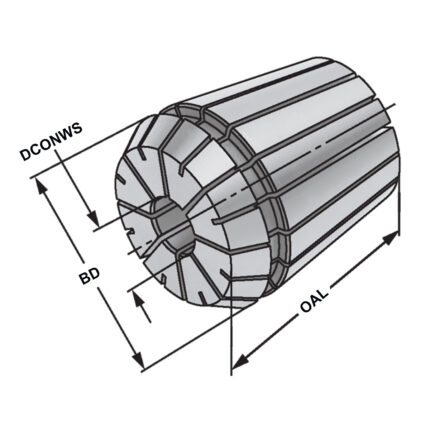

OZ-Precision collet OZ25 | 462EP | < 5µm | O 4 - 3,5

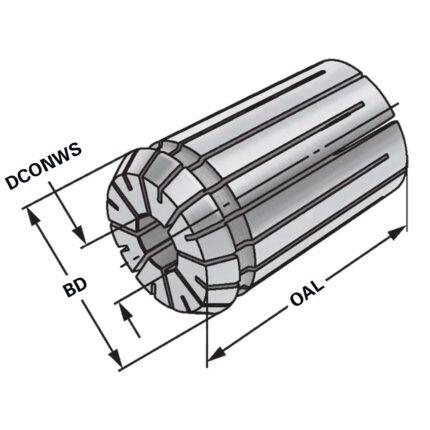

ER-Collet ER 11 | 4008E | < 15µm | O 2,0 - 1,5

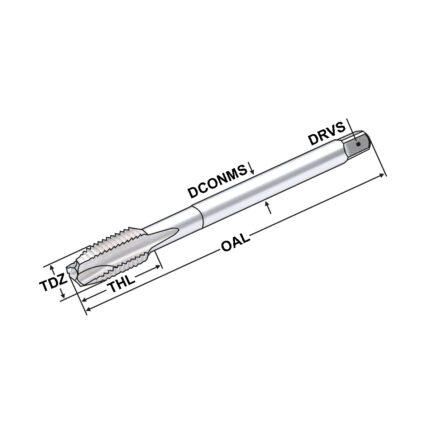

Quick change adaptors with safety clutch Size 1 | M3,5 | 4 x 3 | DIN 371

HSS-E spiral flute taps fine thread M16 12×9 P=1,5 DIN 374

Application:

- Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

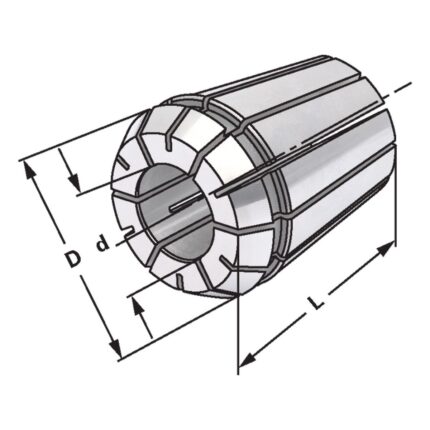

ER-Precision collet ER8 | 4004EP | < 5µm | O 2,5 - 2,0

Shrink chuck 4,5° BT 40 – 08 – 120

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Hydraulic expansion chuck BT 30 – 18 – 90

Hydraulic expansion chucks, BT 30, New items, Hydraulic chucks special offer 2023, ISO 7388-2 [MAS 403 BT]

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Delivery:

With wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

FREE CONSULTATION