Pull studs ~ISO 7388-3 | Form AD | M16 | with drill through | incl. O-ring

Shell mill holder BT 30 – 16 – 40

Application:

For mounting milling cutters with transversal groove.

Note:

DCONWS = 40 and DCONWS = 60:

For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

BT 30 without coolant exit bores on the end face

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant.

For DCONWS = 60 only with four fixation screws according to DIN 912.

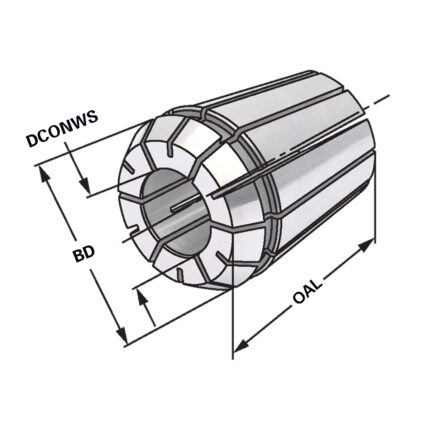

ER-Collet with seal for IC ER40 | 472EA | < 15µm | O 22

Application:

Collets sealed with seal for IC DIN 6499 B (ISO 15488 B) ER-system

Note:

Only nominal size d can be clamped with sealing plug for internal cooling (applicable up to 21 bar) In order to achieve an optimum sealing the tool must be clamped on the complete length of the ground drill of the collet.

ER-Precision collet ER16 | 426EP | < 5µm | O 7 - 6

Depth caliper 0-200mm analogue | mit Feststellschraube

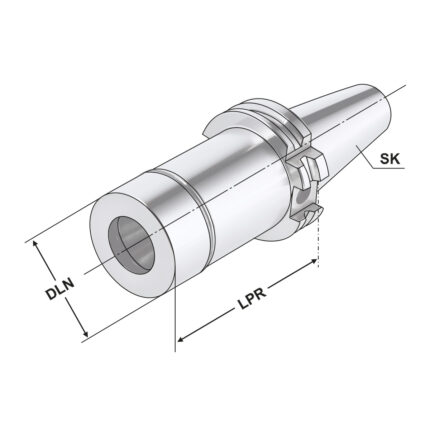

ER-Precision collet chuck SK 50 – 2/20 – 150 | ER 32

Application:

For mounting straight-shank tools in 2 µm-collets.

Advantage:

- Excellent concentricity in the system (chuck + collet + clamping nut)

- 3 µm radial run-out with a 2 µm clamping nut, 6 µm radial run-out with a 5 µm clamping nut

- Extremely strong holding force (increases the holding power by at least 60% compared to standard ER chuck)

- Plain clamping nut without grooves for high speed machining