PART OF CATALOG

Quick change tapping chuck BT 40 – M3-M14 – Gr.1

Application:

For the chucking of quick change adaptors for taps.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

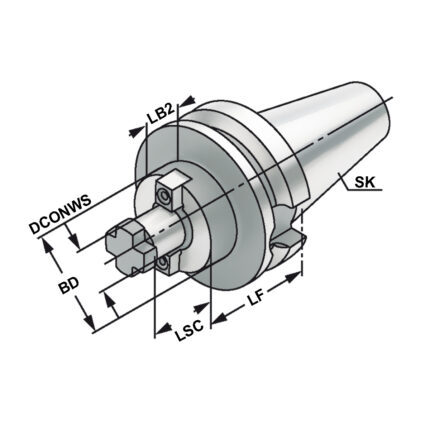

Shell mill holder BT 50 – 32 – 50

Application:

For mounting milling cutters with transversal groove.

Note:

d = 40/d = 60: For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

SK 30 without coolant exit bores on the end face

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant. For d = 60 only with four fi xation screws according to DIN 912.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

HSS-E spiral flute taps M36 28×22 P=3,5

Application:

- Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

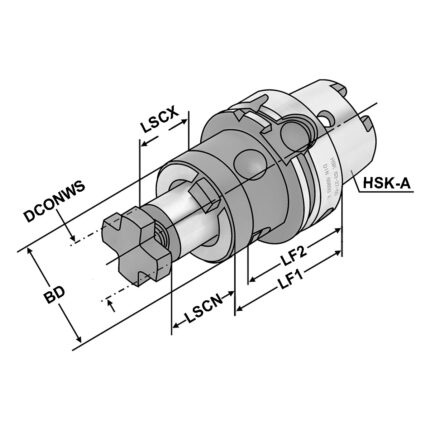

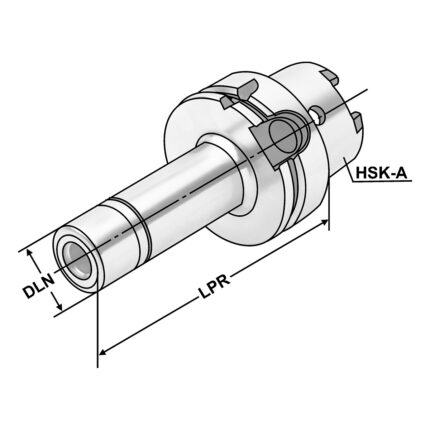

Combi shell mill holder HSK 100 – 16 – 60

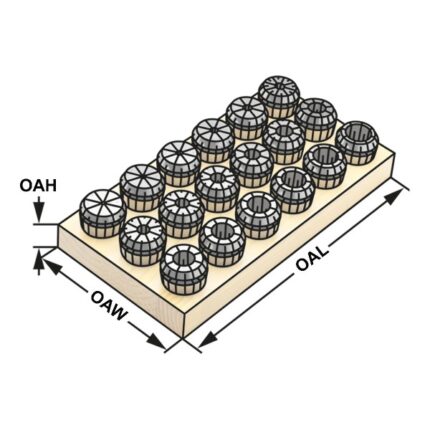

ER-Spannzange mit Kuhlkanalen ER40 | 472ECC | < 15µm | O 20

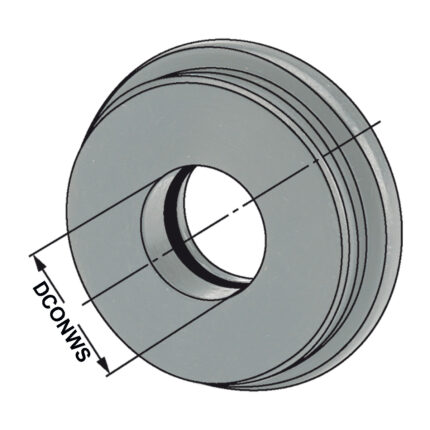

Sealing disc | ER 32 DCONWS = 13,0

KPS-Collet chuck HSK 63 – 1/10 – 160 | KPS 10

Application:

For mounting straight-shank tools in collets. To use for high speed cutting and high precision milling.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

FREE CONSULTATION