PART OF CATALOG

End mill holder Weldon BT 50 – 16 – 160

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

End mill holder Weldon HSK 100 – 16 – 160

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

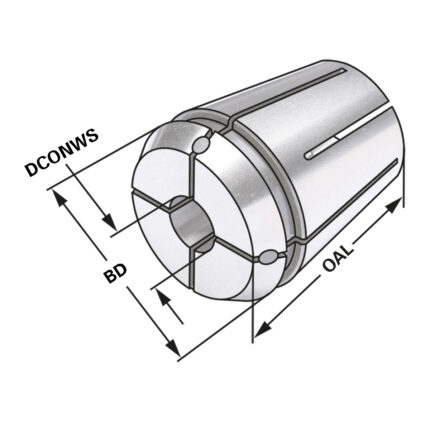

Reduction sleeves for hydraulic expansion chucks DCONMS=32 | DCONWS=8

with coolant channels along the boring, 32mm, Accessories, Accessories for hydraulic chucks, Reducing b. for hydraulic chucks

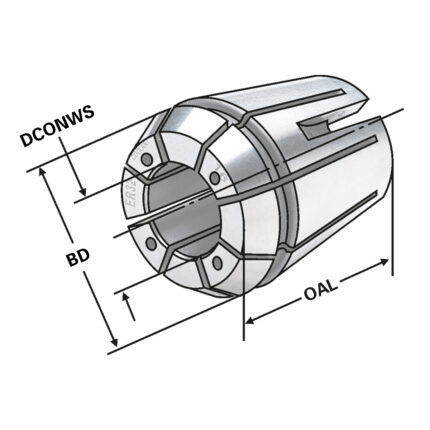

KPS-Prazisionsspannzange KPS 10 | < 5µm | O 8,0-7,5

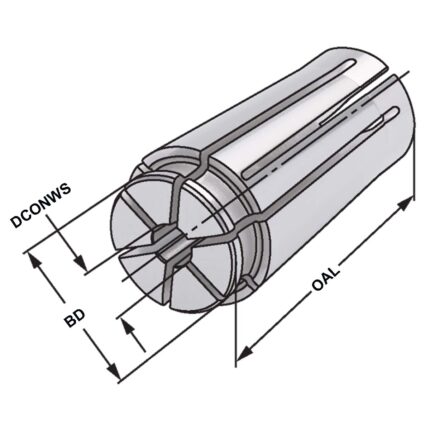

ER-Gewindebohrer-Spannzange IK ER16 | 426GA | < 15µm | 6 x 4,9

FREE CONSULTATION