PART OF CATALOG

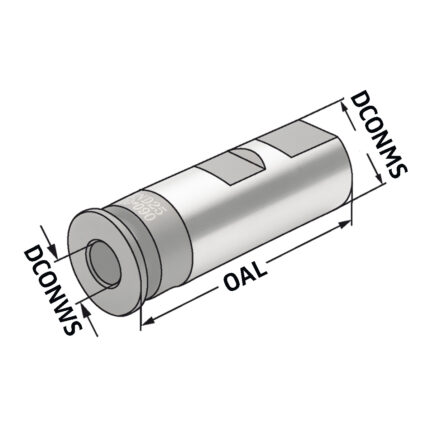

Clamping sleeves for taps with quick change DCONMS=32 | 6 x 4,9

Coolant tube 100mm | Innen O 3mm | M6 Gewinde

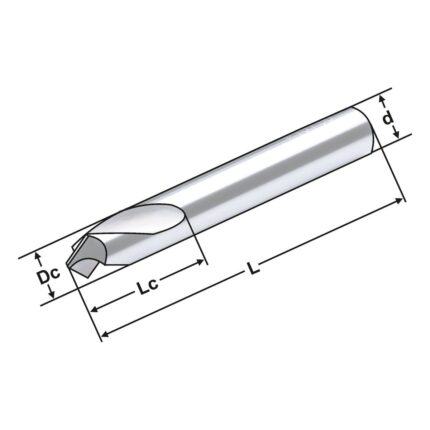

Solid carbide NC spot drill 20mm 90°

Version:

Exactly central ground point. Easy spot drilling and high shape accuracy of the centre hole. Sturdy due to short flutes.

Application:

Point angle 90° for spot drilling and countersinking in one operation when a drill of smaller dia. is used afterwards.

Note:

Use the speed for the actual hole dia. (not generally the speed for the drill outer dia.).

Solid carbide ball nose end mill 2 flutes short 18 R9,0 – 18 AlTiCrN coating

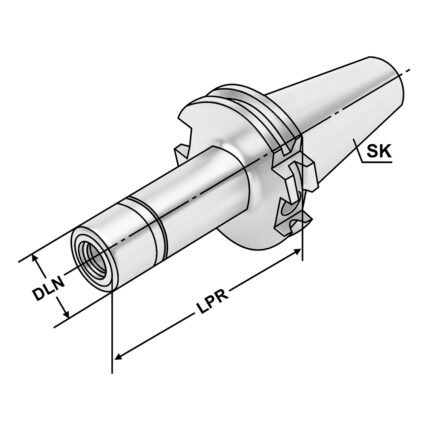

KPS-Collet chuck SK 50 – 4/16 – 165 | KPS 16

Application:

For mounting straight-shank tools in collets. To use for high speed cutting and high precision milling.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

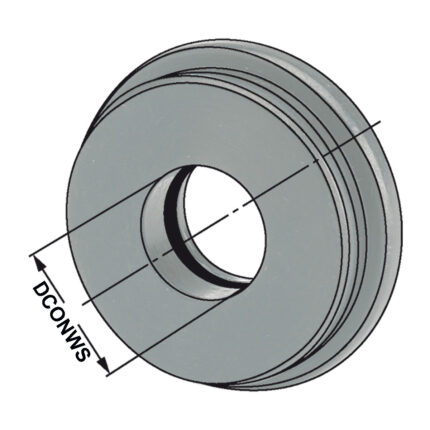

Sealing disc | ER 40 DCONWS = 1,5

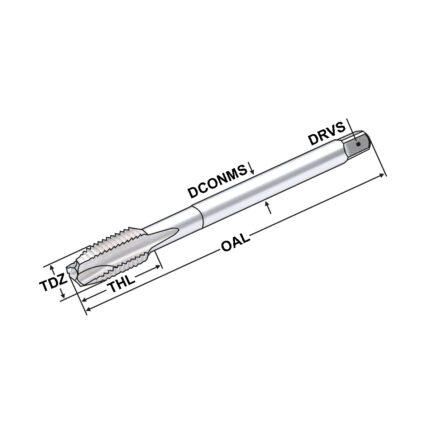

HSS-E spiral flute taps fine thread M16 12×9 P=1,5 DIN 374

Application:

- Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

ER-Precision collet ER40 | 472EP | < 5µm | O 18 - 17

FREE CONSULTATION