PART OF CATALOG

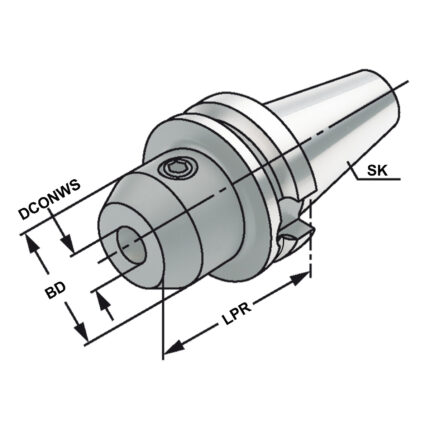

End mill holder Weldon BT 30 – 18 – 63

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Precision vice AVK-160 mechanical with mechanical booster

Ausfuhrung:

- Mit mechanischem Spannkraftverstarker

- Spannkraft voreinstellbar durch Rillenmarkierung

- Horizontal und vertikal aufspannbar

- Stahlkorper allseitig geschliffen und gehartet

- Eingebauter Niederzug

- Betthohe H: 0,01 mm

Delivery:

- Instructions for use

- Wrench

- 4 pcs. vice clamps

- 4 pcs. T-nuts 18 mm

- Test certificate

Pull studs ISO 7388-3 | Form UD | M16 | with drill through | incl. O-ring

Quick change adaptors with safety clutch Size 2 | M18 | 14 x 11 | DIN 376

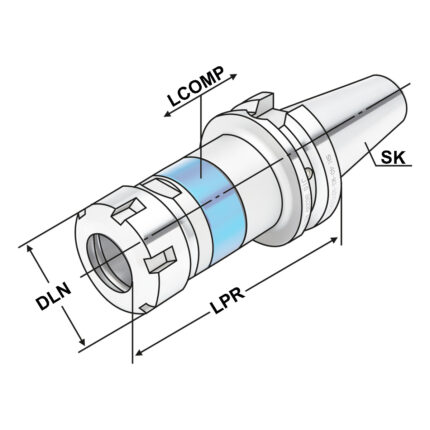

Tapping chucks for synchronisation BT 40 – M3-M27 – 110 | ER 32

Application:

For machining centres with synchronous spindle.

Note:

- Synchro tapping chucks compensate synchronisation errors.

- Minimal length compensation on compression and expansion balances very small pitch differences between synchro spindle and tap, which can cause high frictional forces on the thread flanks.

- A possible increase of axial force during the tapping process is reduced to a minimum.

- Suitable for internal coolant.

- Coolant pressure up to max. 100 bar.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

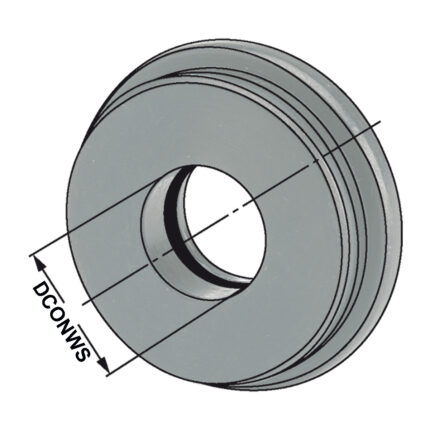

Sealing disc | ER 32 DCONWS = 12,5

Vernier caliper | 0-200mm analogue | with locking screw

FREE CONSULTATION