PART OF CATALOG

Solid carbide 3 flutes short 16mm 16,0 – 16 AlTiCrN coating

Solid carbide ball nose end mill 2 flutes short 3m R1,5 – 6 AlTiCrN coating

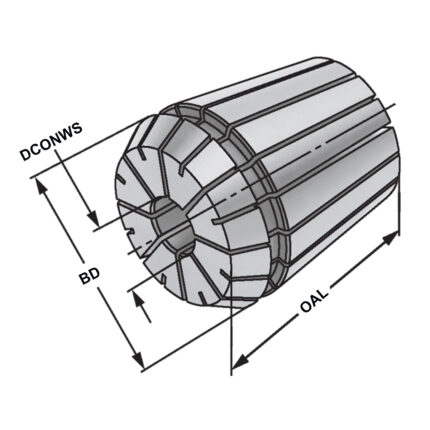

ER-Collet ER32 | 470E | < 15µm | O 9 - 8

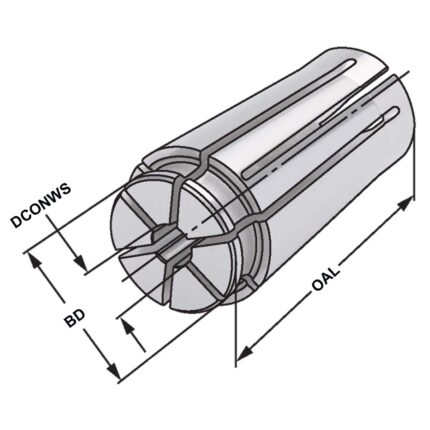

KPS-Prazisionsspannzange KPS 16 | < 5µm | O 8,0-7,5

FREE CONSULTATION