PART OF CATALOG

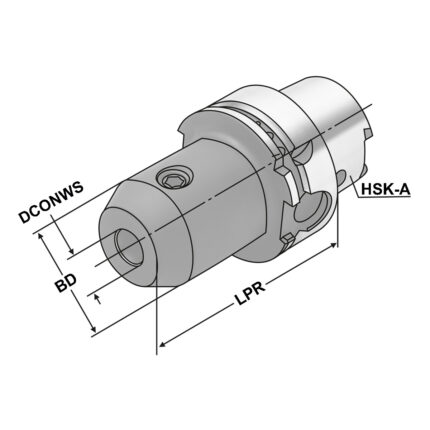

End mill holder Weldon HSK 63 – 06 – 65

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

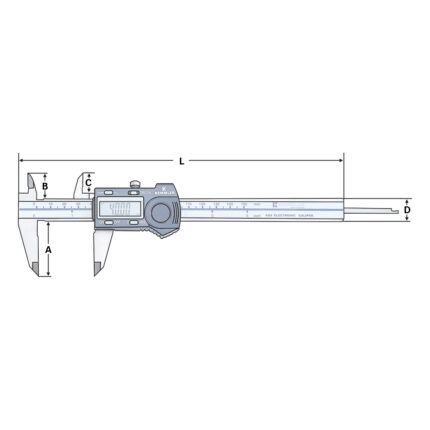

Digital Caliper | 0-150mm with data output | reading 0,01mm

Construction:

- Resolution: .0005" / 0.01mm

- The caliper will be ready for measurements as soon as it is switched on with the LCD screen displaying the actual slider position

- There is no need to set the zero position each time the caliper is used as the origin setting is retained even when the caliper is switched off

- Inch/Metric conversion

- Data output

Delivery:

- Warranty card

- Instruction manual

- Calibration certificate

- CR2032 3,0V Battery

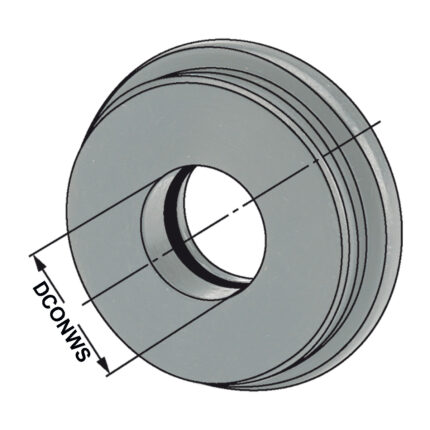

Ring gauge | 47mm ring gauge-accuracy DIN 2250

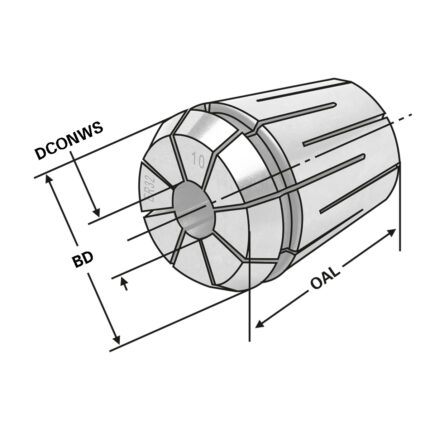

Collets set | 5 µm |ER32 | 470EP | 18-part kit in wooden socket DIN 6499 B (ISO 15488 B)

Sealing disc | ER 32 DCONWS = 13,0

HSS-E spiral flute taps fine thread M12 9×7 P=1,25 DIN 374

Application:

- Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

Shrink chuck 4,5° BT 40 – 05 – 80

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

FREE CONSULTATION