End mill holder Weldon HSK 100 – 16 – 160

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

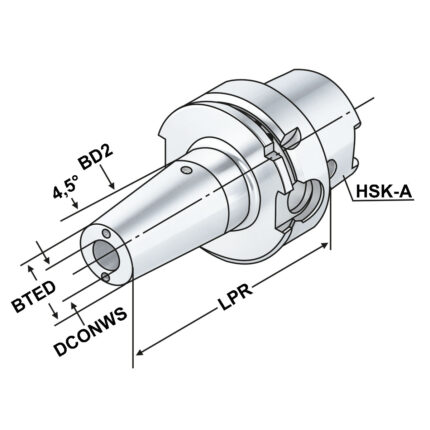

Shrink chuck 4,5° with cooling channels HSK 100 – 20 – 120

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Precision collet sets 462EP (OZ25; 15 parts) in wooden box DIN 6388 B (ISO 10897 B)

Plug gauge | 50mm | H7 accuracy DIN 7162|7164 | size DIN 2245

ER-Collet with seal for IC ER32 | 470EA | < 15µm | O 11

Application:

Collets sealed with seal for IC DIN 6499 B (ISO 15488 B) ER-system

Note:

Only nominal size d can be clamped with sealing plug for internal cooling (applicable up to 21 bar) In order to achieve an optimum sealing the tool must be clamped on the complete length of the ground drill of the collet.

Plug gauge | 9mm | H7 accuracy DIN 7162|7164 | size DIN 2245

Digital Caliper | 30-300mm for inside grooves / with data output

End mill holder Weldon SK 50 – 40 – 100

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined