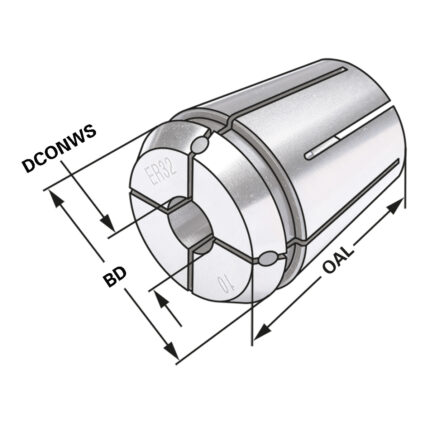

ER-Collet with seal for IC ER25 | 430EA | < 15µm | O 16

Application:

Collets sealed with seal for IC DIN 6499 B (ISO 15488 B) ER-system

Note:

Only nominal size d can be clamped with sealing plug for internal cooling (applicable up to 21 bar) In order to achieve an optimum sealing the tool must be clamped on the complete length of the ground drill of the collet.

Precision vice AVQ-125G/HV mechanical with mechanical booster

Construction:

- With mechanical booster - Clamping force preadjustable by graduation lines

- Clamping positions: horizontal, vertical and lateral

- The steel body is hardened and grinded all-round

- Integrated pull-down mechanism

- Bed height H: 0,01 mm

Delivery:

- Instructions for use

- Wrench

- 4 pcs. vice clamps

- 4 pcs. T-nuts 18 mm

- Test certificate

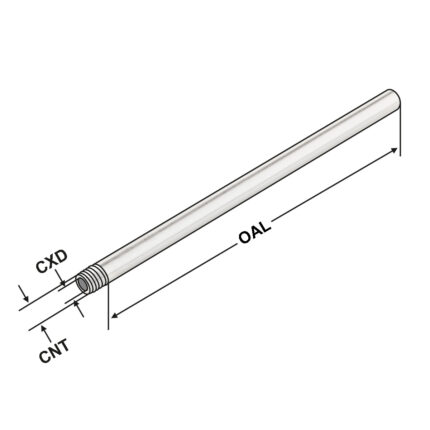

Coolant tube M5 M5 – 3 – 100

Coolant tube HSK 100

Application:

For the coolant supply through the centre of HSK toolholders.

Note:

Axial sealed with two O-rings. After mounting, the coolant tube can be moved only to a minimum degree according to DIN (±1°).

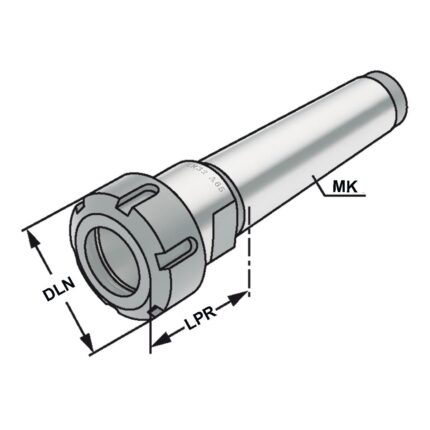

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

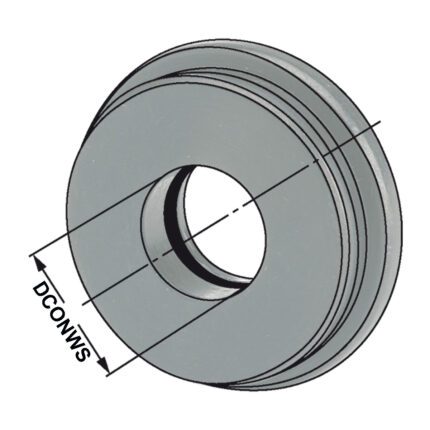

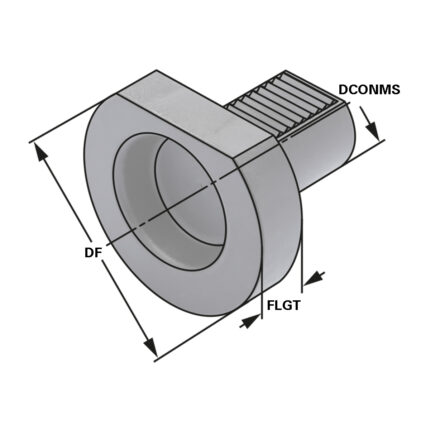

Sealing disc | ER 32 DCONWS = 3,0

Hydraulic expansion chuck HSK 63-32-120 DIN 69893 (ISO 12164) Form A in wooden box

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth

l2 = max. length adjustment range

Delivery:

Without wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined