PART OF CATALOG

ER-Gewindebohrer-Spannzange IK ER32 | 470GA | < 15µm | 6 x 4,9

End mill cutter 75° 40mm – 25mm Shank after DIN 1835B

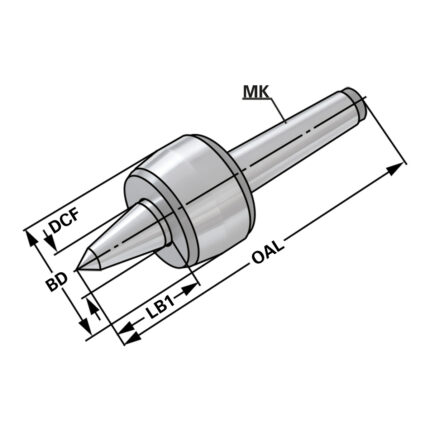

Mitlaufende Drehbankspitze | MK 5 mit verlangerter Spitze

Milling arbors for screw-in cutters HSK 63 – M16 – 101 – LB75

Application:

For mounting screw-in cutters with thread.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Quick change tapping chuck SK 40 – M3-M14 – Gr.1

Application:

For the chucking of quick change adaptors for taps.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

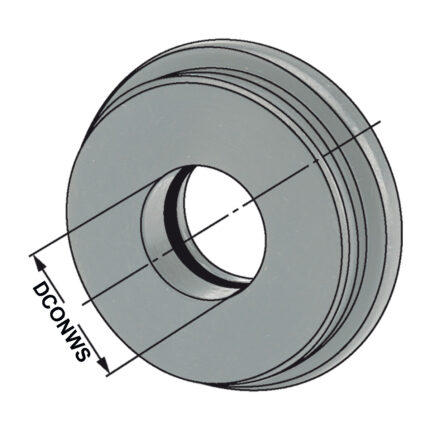

Sealing disc | ER 40 DCONWS = 4,0

Morse taper adaptor HSK 63 – 4 – 160

Application:

For mounting tools with Morse taper shank and tang according to DIN 228-1 form B.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

FREE CONSULTATION