PART OF CATALOG

Kantentaster elektronisch 3D 16 – 111 – 10

Application:

Alignment of component reference surfaces or edges. Determination of bore centres to the machine spindle.

Note:

The spring-mounted spherical tip protects the unit from damage if contact is too strong. Functional parts hardened and ground. Concentricity: ± 0.01 mm.

When contact between the spherical tip and metal component occurs, the control lamp lights up = identification of the reference point.

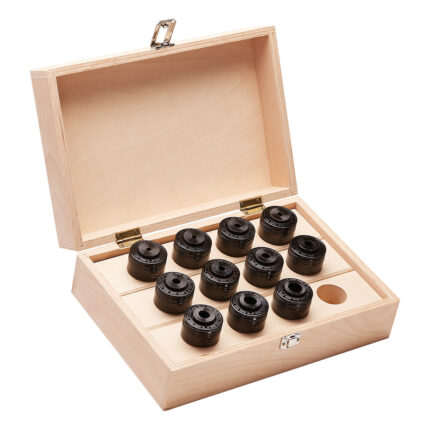

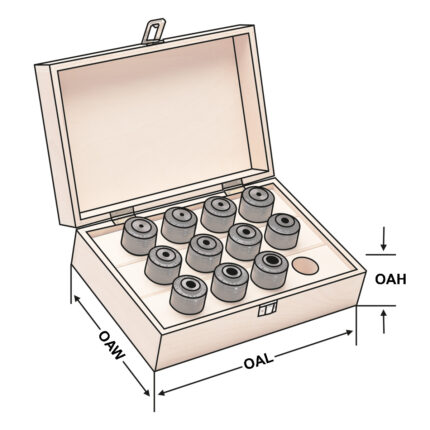

Quick-change adaptors without clutch Set of 9 pieces M14/M36 Gr.3

ER-Precision collet | stainless steel ER32 | 470ESP | < 5 µm | O 15,0 - 14,5

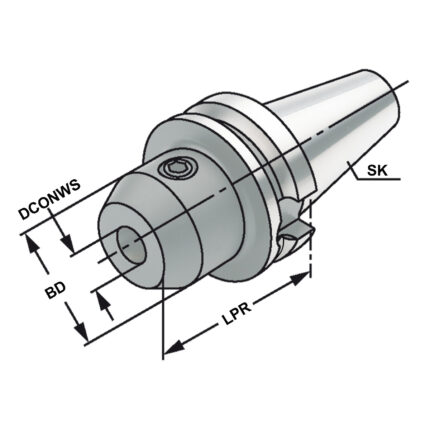

End mill holder Weldon with cooling channels BT 40 – 10 – 100

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw and O-ring

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

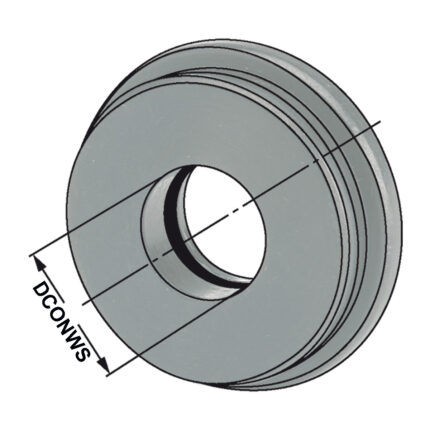

Sealing disc | OZ 16 DCONWS = 5,5

FREE CONSULTATION