PART OF CATALOG

Sealing disc | OZ 25 DCONWS = 11,5

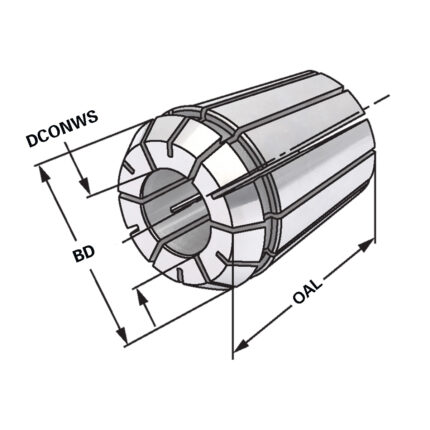

ER-Precision collet ER25 | 430EP | < 5µm | O 4 - 3

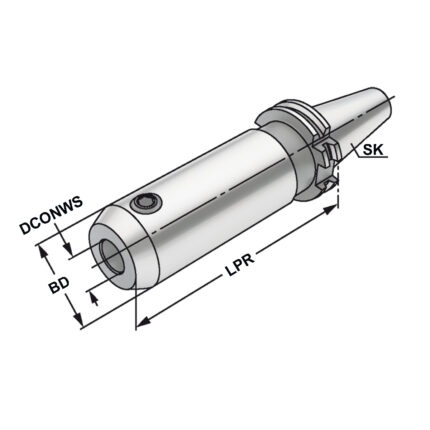

End mill holder Weldon with cooling channels SK 50 – 16 – 130

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw and O-ring

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

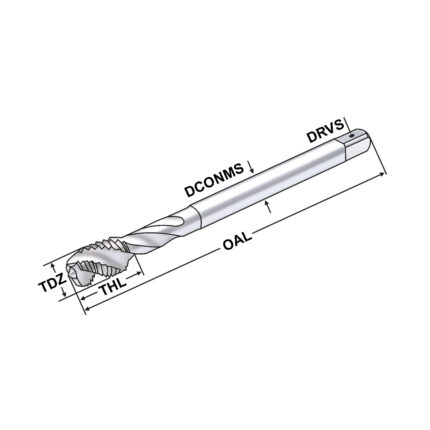

HSS-E spiral flute taps fine thread M6 4,5×3,4 P=0,5 DIN 374

Application:

- Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

FREE CONSULTATION