PART OF CATALOG

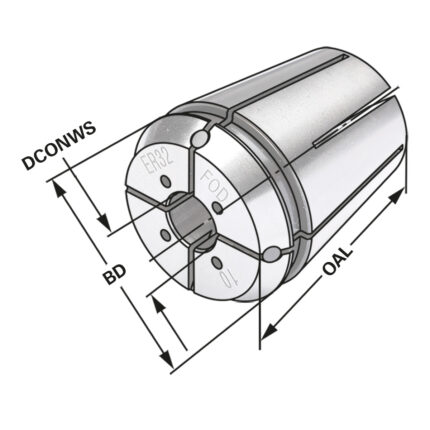

ER-Collet with cooling channel holes ER16 | 426EC | < 15µm | O 6

ER-Collet with cooling channel holes ER32 | 470EC | < 15µm | O 17

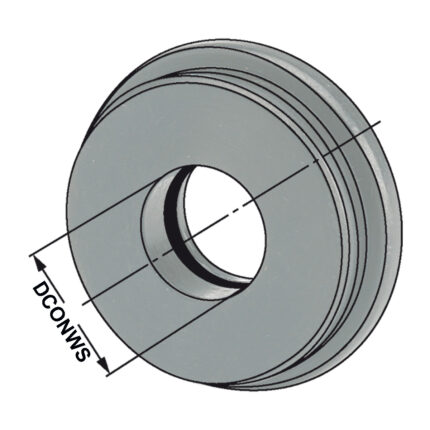

Sealing disc | ER 40 DCONWS = 23,5

High Performance Milling Chuck HSK-A 100-25-105 DIN 69893 Form A HKS-system in wooden box

Reduction sleeves for hydraulic expansion chucks DCONMS=20 | DCONWS=8

with coolant channels along the boring, 20mm, Accessories, Accessories for hydraulic chucks, Reducing b. for hydraulic chucks

Shrink chuck 4,5° HSK 50 – 12 – 90

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

ER-Collet chuck HSK 63 – 2/16 – 130 | ER 25

Application:

For mounting straight-shank tools in collets.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

FREE CONSULTATION