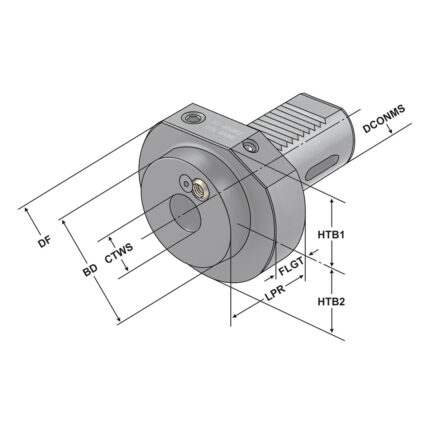

Hydraulic expansion chuck BT 40 – 16 – 150

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Without wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

HSS-E spiral flute taps M24 18×14 P=3,0

Application:

- Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

HSS-E spiral flute taps fine thread M14 11×9 P=1,5 DIN 374

Application:

- Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

3D-Taster analog 12mm Schaft

Der 3D-Taster besticht durch sein schlankes und attraktives Design. Seine prazisen und vielseitigen Einsatzmoglichkeiten erlauben schnelles und einfaches Ermitteln von Werkstucknullpunkten und Langenma?en.

Die Antastung ist in allen Achs-Richtungen (X/Y/Z) bei gleicher Zeigerauflosung moglich.

Sobald die Zeiger 0" anzeigen, steht die Spindelachse prazise auf der Werkstuckkante.

Der Schutz der Messeinheit steht im Vordergrund. Hierzu wurden gro?e Uberfahrwege in die Tasteinheit integriert. Diese sind durch mechanische Endanschlage begrenzt. Der Tasteinsatz hat eine Sollbruchstelle, die ganz weit oben angebracht ist. Sollte Ihr 3D-Taster durch au?ere Krafteinwirkung trotzdem beschadigt werden, so ist eine einfache Reparatur kostengunstig moglich.

Hinweis:

- not waterproof

- without test certificate

- without serial number

OZ-Collet OZ32 | 467E | < 15µm | O 23 - 22,5

Morse taper adaptor – form F1 F1 – 30 – MK3

Shrink chuck 4,5° HSK 50 – 05 – 80

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined