PART OF CATALOG

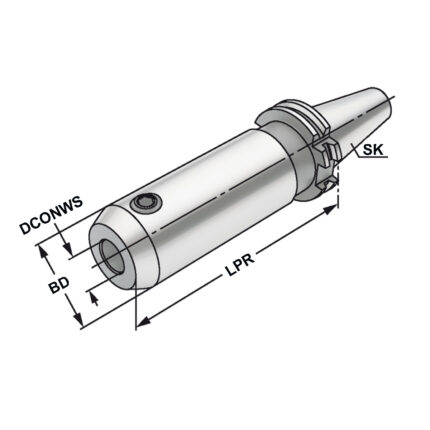

End mill holder Weldon with cooling channels BT 40 – 08 – 100

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw and O-ring

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

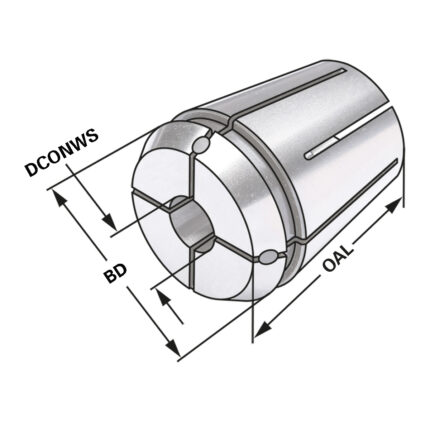

OZ-Precision collet OZ25 | 462EP | < 5µm | O 10 - 9,5

Claw jaws set (Pair) for ATW-50 / ATD-570

Version:

Jaws with grip serrations und fine step for workpieces with max. edge radius 1 mm, clamping depth 2 mm

- For use on vises

- Simple, safe clamping of parallel raw and sawn parts

- Hydraulic or manual clamping

- Positive clamping due to penetration of the hardened claw tips

- High holding forces: increase by a factor of 3 to 5 compared to standard jaws

- Low material loss

- Shortened processing times and reduction of production and unit costs

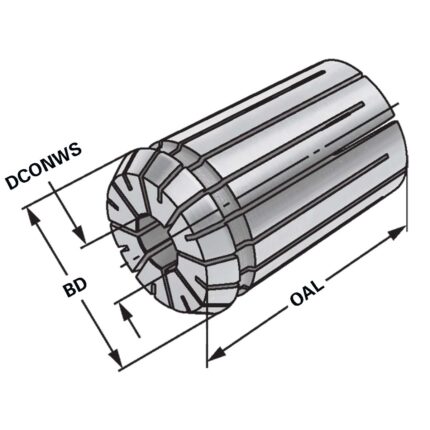

ER-Precision collet ER25 | 430EP | < 5µm | O 11 - 10

Ring gauge | 58mm ring gauge-accuracy DIN 2250

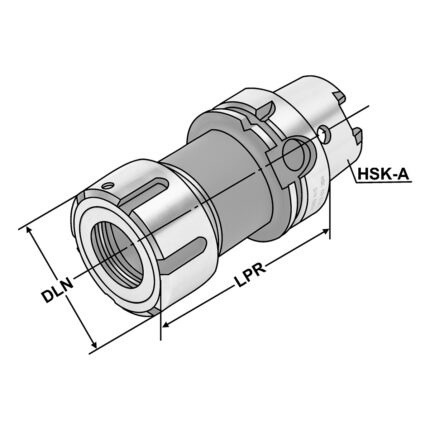

OZ-Collet chuck HSK 100 – 2/25 – 120 | OZ 25

Application:

For mounting straight-shank tools in collets.

Delivery:

With ball bearing clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

ER-Gewindebohrer-Spannzange IK ER32 | 470GA | < 15µm | 9 x 7

FREE CONSULTATION