PART OF CATALOG

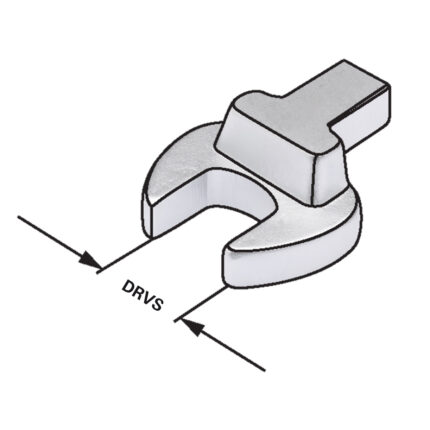

Milling arbors for screw-in cutters SK 40 – M10 – 169 – LB150

Application:

For mounting screw-in cutters with thread.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

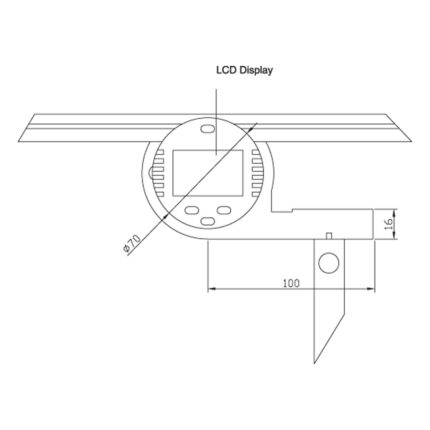

Digital protractor 0-360° with fine adjustment

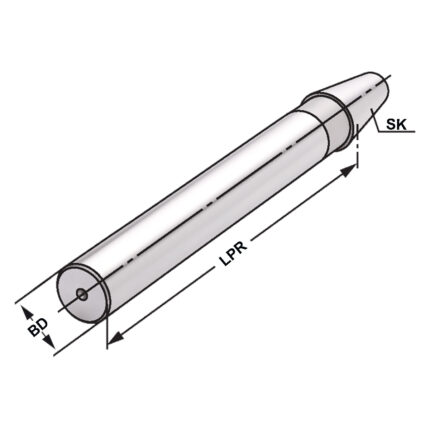

Test arbor SK 40 – 40 – 302

Pull studs ~ISO 7388-3 | Form AD | M16 | with drill through | incl. O-ring

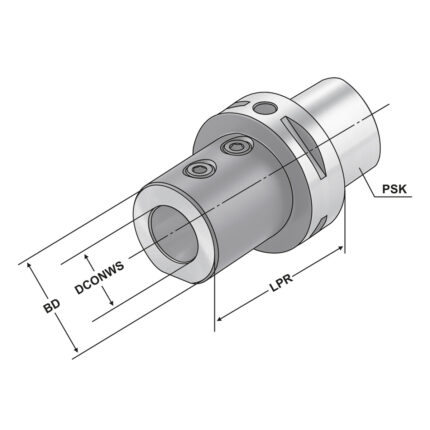

Boring holder for drills with indexable inserts | PSK 63 – 40 – 85

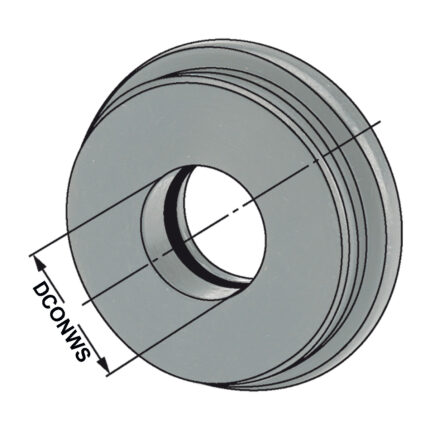

Combi shell mill holder SK 50 – 16 – 55

Application:

For mounting milling cutters with transverse or longitudinal groove.

Delivery:

With retaining screw, driving ring and feather key

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

FREE CONSULTATION