Hydraulic expansion chuck SK 30-20-90 DIN 69871 AD/B in wooden box

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Delivery:

With wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

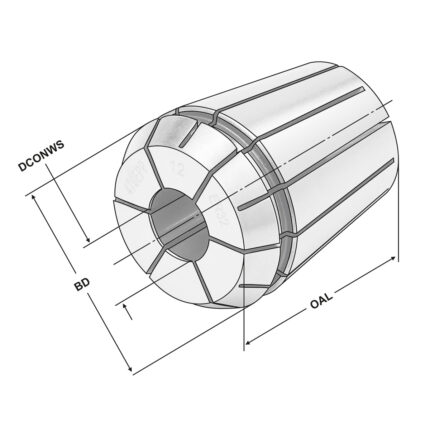

ER-Precision collet ER32 | 470EPP | < 3 µm | O 14,5

Application:

For mounting straight-shank tools in collet chucks ISO 15488 (ex. DIN 6499).

Version:

System concentricity and repetition accuracy 3 µm (3?D, maximum = 50 mm), in conjunction with KEMMLER Precision collet chuck ER".

Suitable for:

KEMMLER Precision collet chuck ER or standard collet chuck Spannfutter ISO 15488 (ex. DIN 6499).

Note:

The collet clamping O range is always up to 0.5 mm less than nominal.

Shrink chuck 4,5° HSK 32 – 12 – 90

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined