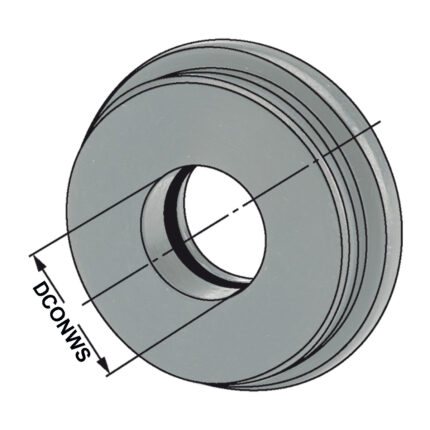

Sealing disc | ER 40 DCONWS = 14,5

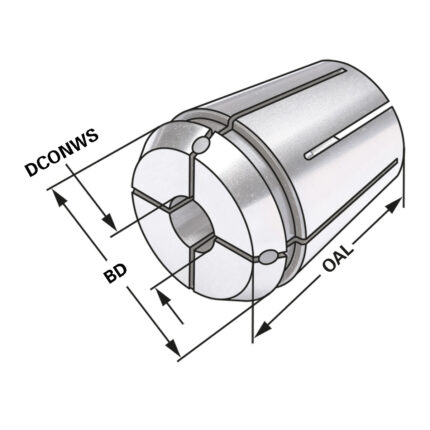

ER-Gewindebohrer-Spannzange IK ER20 | 428GA | < 15µm | 10 x 8

Ring gauge | 3mm ring gauge-accuracy DIN 2250

Morse taper adaptor BT 50 – 3 – 65

Application:

For clamping tools with Morse taper shank and thread according to DIN 228-1 form A.

Delivery:

With built-in tightening bolt

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Shell mill holder SK 40 – 16 – 100

Application:

For mounting milling cutters with transversal groove.

Note:

d = 40/d = 60: For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant. For d = 60 only with four fi xation screws according to DIN 912.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

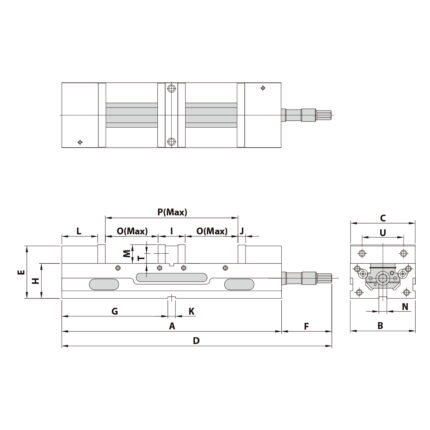

Twin vice TLD-40G/HV mechanical

Construction:

- Double-clamping via two mobile and one fixed jaw.

- Clamping positions: horizontal, and vertical

- The steel body is hardened and grinded all-round

- Integrated pull-down mechanism

- Repeating accuracy 0,01 mm

- Clamping accuracy at the centre 0,01 mm

- Bed height H: 0,01 mm

Delivery:

- Instructions for use

- Wrench

- 4 pcs. vice clamps

- 4 pcs. T-nuts 18 mm

- Test certificate

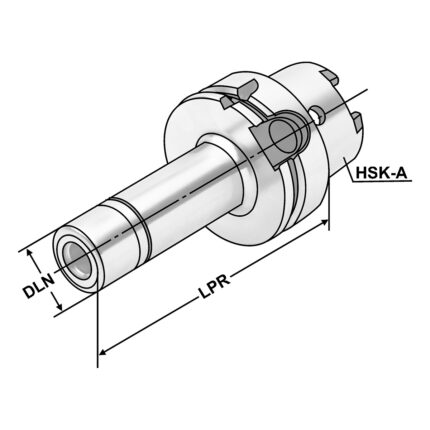

KPS-Collet chuck HSK 50 – 1/10 – 60 | KPS 10

Application:

For mounting straight-shank tools in collets. To use for high speed cutting and high precision milling.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined