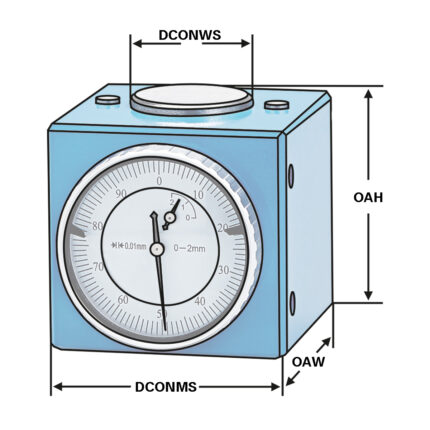

Z-Zero-setter with magnet

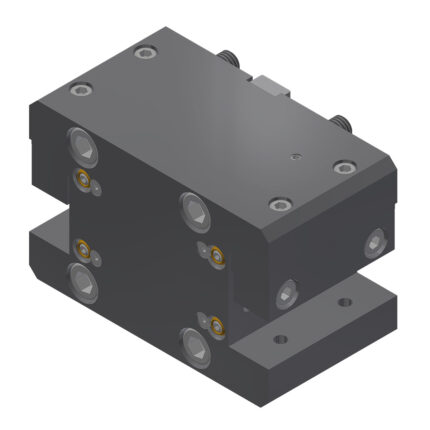

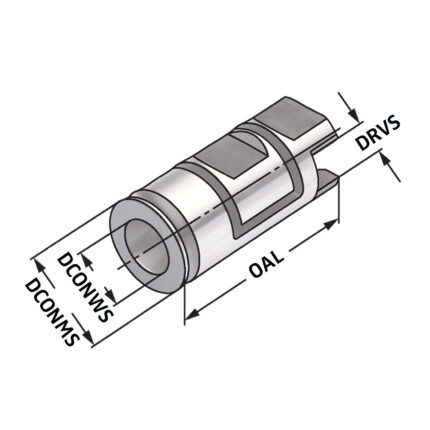

End mill holder Weldon with cooling channels SK 40 – 14 – 50

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw and O-ring

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

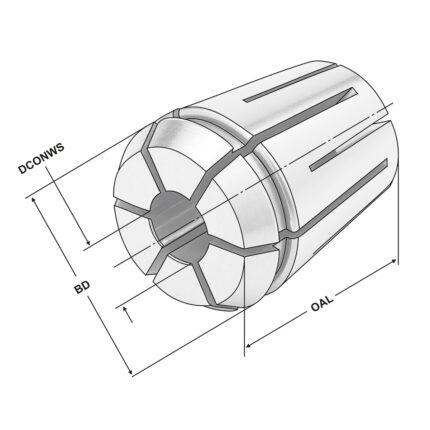

Shell mill holder SK 40 – 32 – 50

Application:

For mounting milling cutters with transversal groove.

Note:

d = 40/d = 60: For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant. For d = 60 only with four fi xation screws according to DIN 912.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

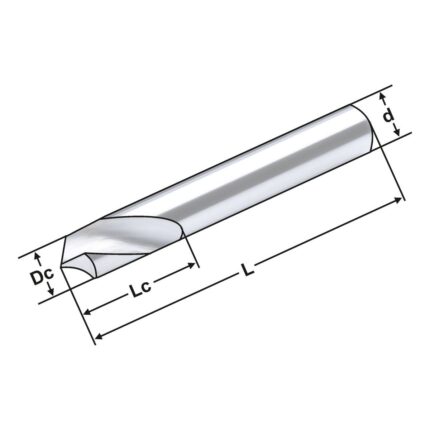

Solid carbide NC spot drill 6mm 120°

Version:

Exactly central ground point. Easy spot drilling and high shape accuracy of the centre hole. Sturdy due to short flutes.

Application:

Point angle 120° for spot drilling and countersinking in one operation when a drill of smaller dia. is used afterwards.

Note:

Use the speed for the actual hole dia. (not generally the speed for the drill outer dia.).

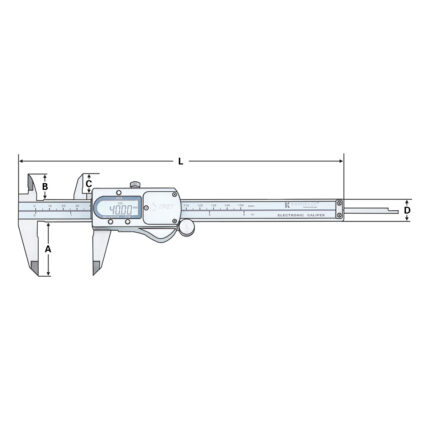

Digital Caliper | 0-300mm IP67 | reading 0,01mm

Construction:

- Resolution: .0005" / 0.01mm

- Conforms to the IP67 ratings

- Extra large LCD readout

- Inch/Metric conversion

- The design allows the caliper to be used in normal workshop conditions and is resistant to coolant, water, dust or oil

- Automatic switch off

Delivery:

- Warranty card

- Instruction manual

- Calibration certificate

- CR2032 3,0V Battery

- Screwdriver