PART OF CATALOG

ER-Precision collet ER11 | 4008EP | < 5µm | O 1,0 - 0,5

CNC-Werkzeugeinsatz | HSK 63-A+F | PSK

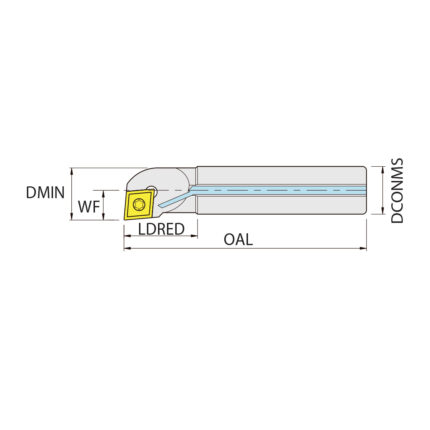

Milling arbors for screw-in cutters BT 40 – M10 – 77 – LB50

Application:

For mounting screw-in cutters with thread.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

ER-Spannzange mit Kuhlkanalen ER40 | 472ECC | < 15µm | O 10

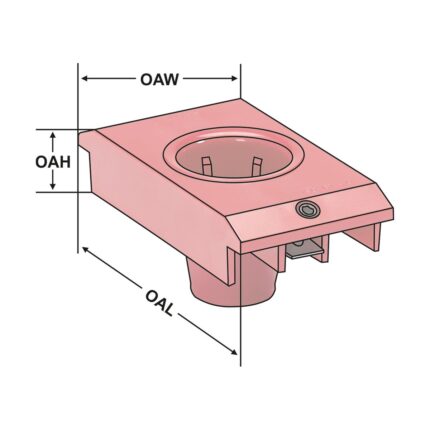

Hydraulic expansion chuck HSK 100 – 20 – 150

Hydraulic expansion chucks, HSK-A 100, New items, Hydraulic chucks special offer 2023, ISO 12164 (HSK-A)

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth

l2 = max. length adjustment range

Delivery:

Without wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

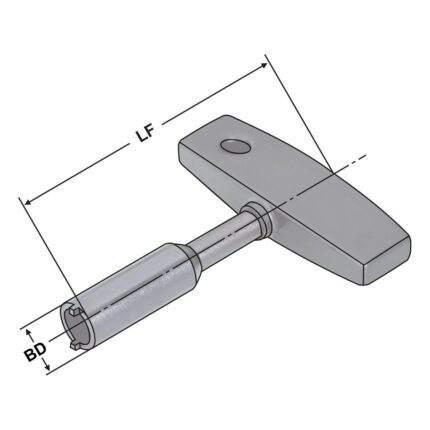

Key for coolant tube HSK 100

Application:

For mounting the coolant tubes in HSK toolholders.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

FREE CONSULTATION