PART OF CATALOG

Claw jaws set (Pair) for ATW-675 | ATW-689 | MG-60 | AM-C60 | TLD-60

Version:

Jaws with grip serrations und fine step for workpieces with max. edge radius 1 mm, clamping depth 2 mm

- For use on vises

- Simple, safe clamping of parallel raw and sawn parts

- Hydraulic or manual clamping

- Positive clamping due to penetration of the hardened claw tips

- High holding forces: increase by a factor of 3 to 5 compared to standard jaws

- Low material loss

- Shortened processing times and reduction of production and unit costs

Morse taper adaptor SK 40 – 4 – 95

Application:

For mounting tools with Morse taper shank and tang according to DIN 228-1 form B.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

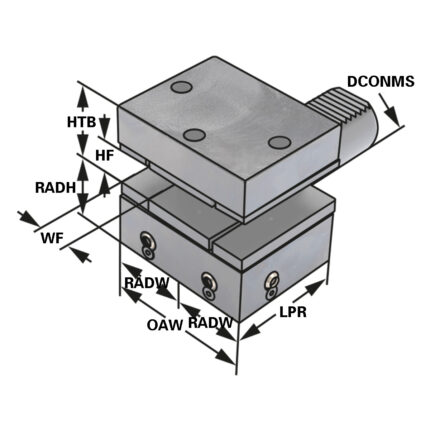

Vierkant-Mehrfach-Aufnahme – form D2 overhead 30 – 20 – 60

Shrink chuck 4,5° SK 50 – 06 – 200

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

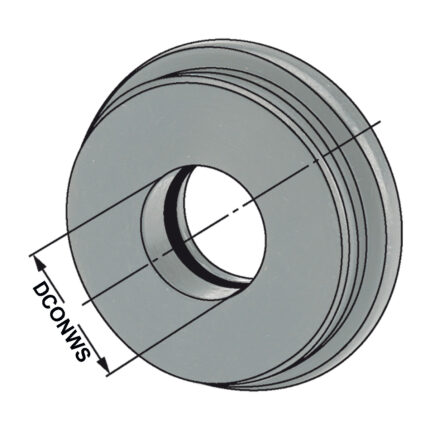

Sealing disc | ER 40 DCONWS = 2,5

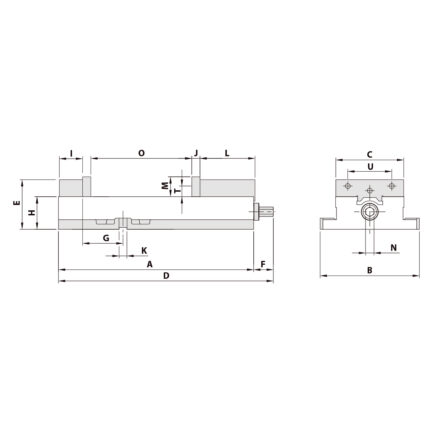

Precision vice ATW-810A mechanical

Milling arbors for screw-in cutters SK 40 – M8 – 119 – LB100

Application:

For mounting screw-in cutters with thread.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

FREE CONSULTATION