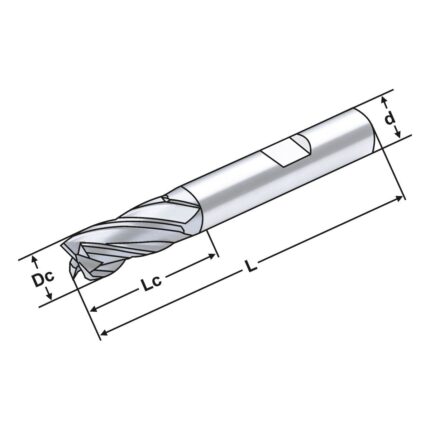

Solid carbide 4 flutes long 16mm 16,0 – 16 AlTiCrN coating

ER-Collet with seal for IC ER40 | 472EA | < 15µm | O 25

Application:

Collets sealed with seal for IC DIN 6499 B (ISO 15488 B) ER-system

Note:

Only nominal size d can be clamped with sealing plug for internal cooling (applicable up to 21 bar) In order to achieve an optimum sealing the tool must be clamped on the complete length of the ground drill of the collet.

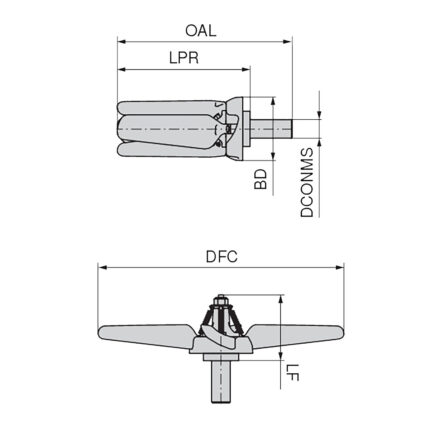

Cleaning propeller | Chip Blower O 16mm – 160mm

Version:

- Robust design

- Opening and closing of the flanks through the spindle speed control

- For use in any tool holder O16mm with a center coolant

- Body made of high strength and anodized aluminum

Advantages:

- Efficient cleaning of clamping equipment, pieces and tables

- Removal of chips und cleaning of water pockets

- Perfekte update to the automated work process

Drehzahlbereich (Empfehlung): Min. 7.000 / Max. 12.000 rpm

Rotationsrichtung: Uhrzeigersinn

Entfernung zwischen geoffneten Flugeln und Spahnen: 100~150 mm

Vorschub (Empfehlung): 1.000~3.000 mm/min

Ideal fur kleine Werkzeugmaschinen mit wenig Spahnen und Kuhlung

Zubehor/Ersatzteil:

Art.Nr.: ERS.900.90.160

Ersatz-Reinigungs-Propeller Typ 160mm

Lieferumfang:

1 Stk. Rotorblatt; Inklusive Feder, Positionier- und Halte-Pin

Quick change adaptors without safety clutch Size 2 | 6 x 4,9

KPS-Prazisionsspannzange KPS 16 | < 5µm | O 11,5-11,0

ER-Collet chuck BT 40 – 2/13 – 100 | ER 20

Application:

For mounting straight-shank tools in collets.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined