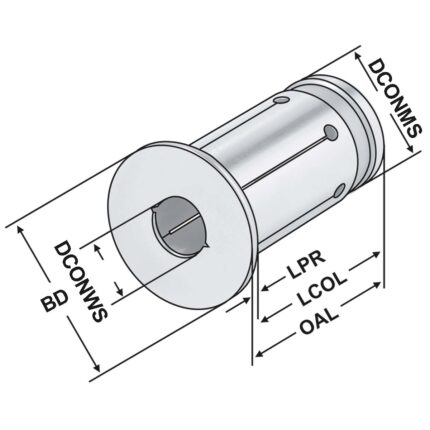

Reduction sleeves for Milling Chuck DCONMS=20 | DCONWS=5

Cleaning propeller | Chip Blower O 16mm – 330mm

Version:

- Robust design

- Opening and closing of the flanks through the spindle speed control

- For use in any tool holder O16mm with a center coolant

- Body made of high strength and anodized aluminum

Advantages:

- Efficient cleaning of clamping equipment, pieces and tables

- Removal of chips und cleaning of water pockets

- Perfekte update to the automated work process

Drehzahlbereich (Empfehlung): Min. 4.000 / Max. 7.000 rpm

Rotationsrichtung: Uhrzeigersinn

Entfernung zwischen geoffneten Flugeln und Spahnen: 100~150 mm

Vorschub (Empfehlung): 3.000~15.000 mm/min

Ideal fur gro?e Werkzeugmaschinen mit vielen und schwer zu entfernenden Spahnen

Zubehor/Ersatzteil:

Art.Nr.: ERS.900.90.330

Ersatz-Reinigungs-Propeller Typ 330mm

Lieferumfang:

1 Stk. Rotorblatt; Inklusive Feder, Positionier- und Halte-Pin

Universal ball bearing tightening fixture for HSK-A50 – HSK-E50 – HSK-F50 – C5

Application:

For easy and reliable clamping of tool arbors at the collar using rollers to mount and remove cutting tools - friction lock is self-clamping and ideal for HSK forms E and F, and also polygon shank arbors.

Suitable for:

For all popular tool arbors such as SK (DIN 69871), HSK (forms A, B, C, D, E, F), polygon shanks, MAS/BT (JIS B 6339), and CAT (ANSI B5.50).

Note:

Max. tightening torque 150 Nm

Sealing disc | OZ 32 DCONWS = 30,0

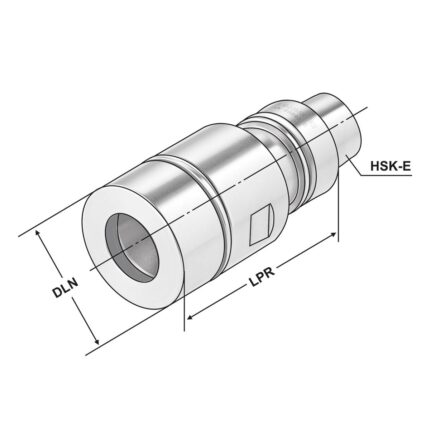

ER-Precision collet chuck HSK 50 – 2/20 – 70 | ER 32

Application:

For mounting straight-shank tools in 2 µm-collets.

Advantage:

- Excellent concentricity in the system (chuck + collet + clamping nut)

- 3 µm radial run-out with a 2 µm clamping nut, 6 µm radial run-out with a 5 µm clamping nut

- Extremely strong holding force (increases the holding power by at least 60% compared to standard ER chuck)

- Plain clamping nut without grooves for high speed machining

HSS-E spiral flute taps M8 8×6,2 P=1,25

Application:

1. Thread configuration with a special design, prevents overfeeding, thin thread and pitch diameter oversize.

2. Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

3. Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel