PART OF CATALOG

CNC Tischaufsatzgestell – 2 Kassetten 575 x 375 x 300 – Fur E1, E2 und E3

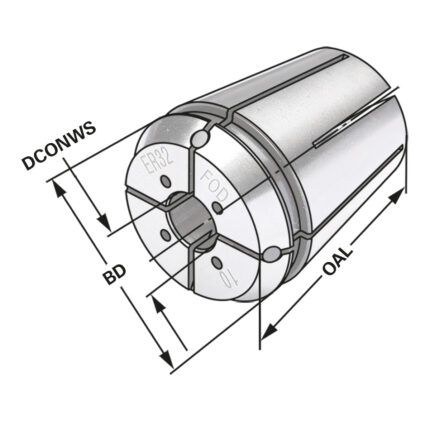

ER-Collet with cooling channel holes ER32 | 470EC | < 15µm | O 19

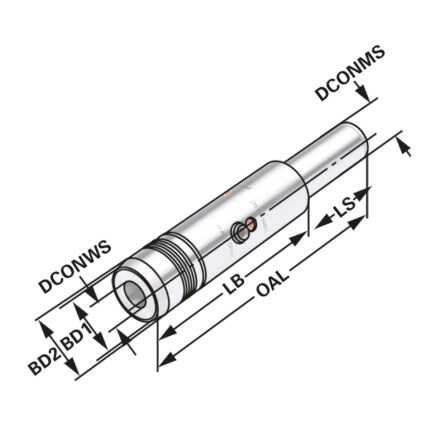

HSS-E spiral flute taps fine thread M4 2,8×2,1 P=0,5 DIN 374

Application:

- Thread configuration with a special design, prevents over-feeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

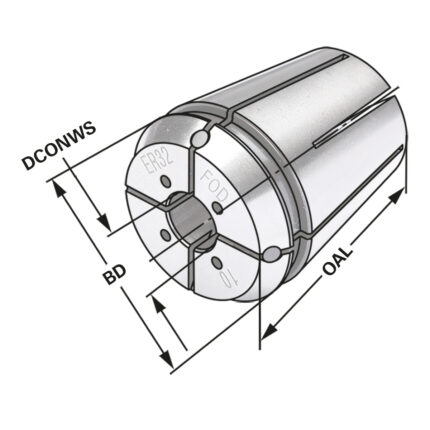

ER-Collet with cooling channel holes ER32 | 470EC | < 15µm | O 10

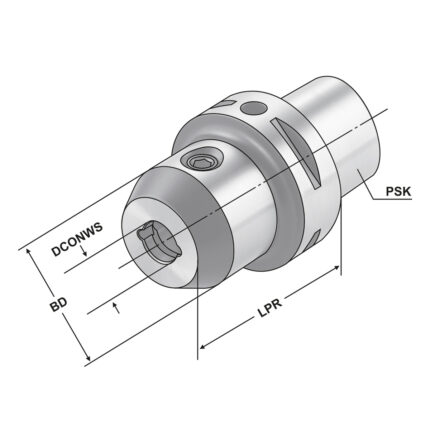

Hydraulic expansion chuck 20 – 16 – 100

ER-Collet chuck HSK 40 – 2/16 – 75 | ER 25

Application:

For mounting straight-shank tools in collets.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

FREE CONSULTATION