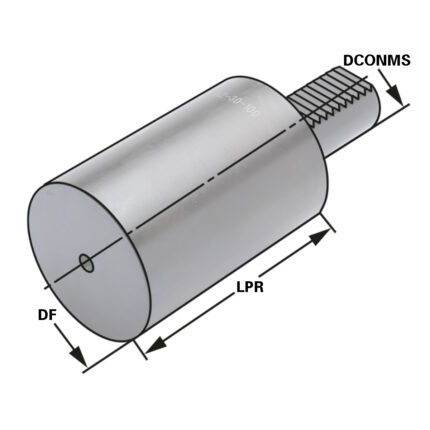

ER-Spannzange mit Kuhlkanalen ER40 | 472ECC | < 15µm | O 16

CNC Werkzeugeinsatze | Typ 2 Zyl / VDI 50

The tool inserts are made of oil-resistant,

break-proof and impact-resistant ABS plastic

and are noted for their tailored inner struts.

The tapered tool holder is thus optimally

centred.

The insert is clicked into our grid system with

a clip and can be moved in steps of 25 mm

without a tool.

Nubs on the top of the inserts.

In this way, no adhesion occurs and the tool

is prevented from attaching itself by vacuum

All tool sizes can be combined

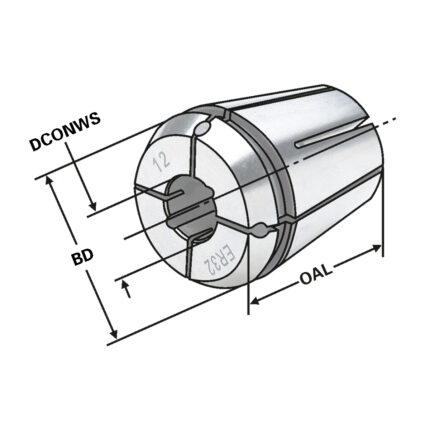

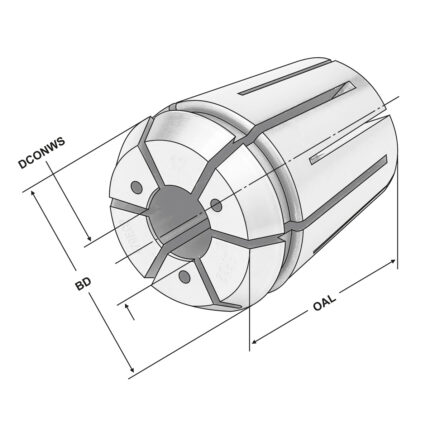

ER-Precision collet with cooling channels ER32 | 470ECP | < 3 µm | O 11,0

Application:

For mounting straight-shank tools in collet chucks ISO 15488 (ex. DIN 6499).

Version:

Metallic sealed collets with cooling channels. Applicable up to 100 bar.

System concentricity and repetition accuracy 3 µm (3?D, maximum = 50 mm), in conjunction with KEMMLER Precision collet chuck ER".

Suitable for:

KEMMLER Precision collet chuck ER or standard collet chuck Spannfutter ISO 15488 (ex. DIN 6499).

Note:

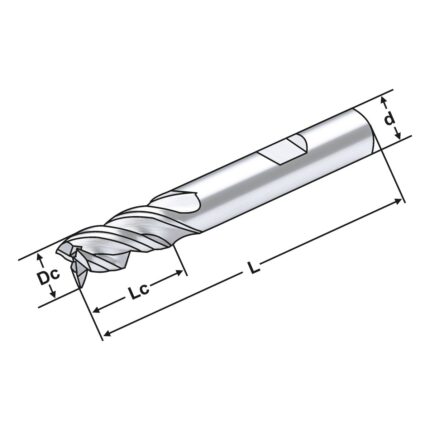

Only nominal size d can be clamped, with cooling channels. In order to achieve an optimum sealing the tool must be clamped on the complete length of the ground drill of the collet. Applicable up to 100 bar.