Radial toolholder – form B4 overhead left short B4 – 30 x 20 x 40

Application:

Mainly for external machining. For face machining.

Precision coolant supply: Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.With high precision coolant you get improved

chip breaking, longer tool life, better process security and productivity. Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.

End mill holder Weldon PSK 50 – 06 – 50

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

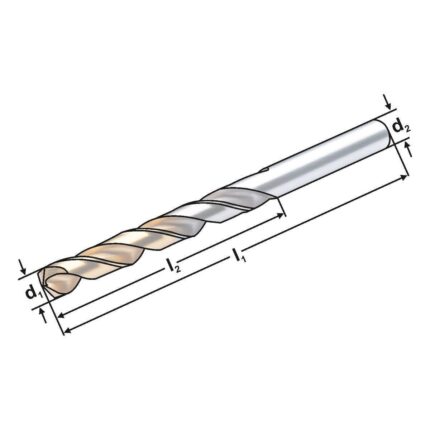

HSSE twist drill 135° 9,4 mm DIN 338 | TIN coating

OZ-Precision collet OZ16 | 415EP | < 5µm | O 13 - 12,5

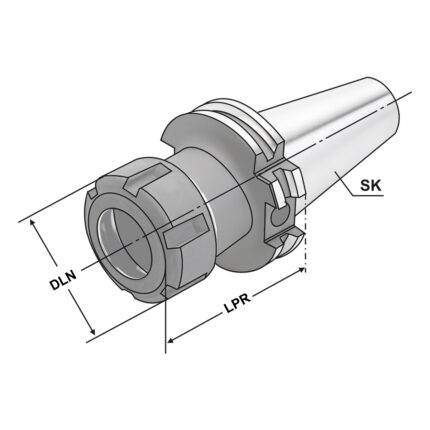

ER-Collet chuck SK 30 – 1/10 – 70 | ER 16

Application:

For mounting straight-shank tools in collets.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Grinding and inspection vices with quick adjustment 50 mm

Shrink chuck 4,5° HSK 100 – 05 – 85

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined