PART OF CATALOG

Solid carbide 3 flutes short 10mm 10,0 – 10 AlTiCrN coating

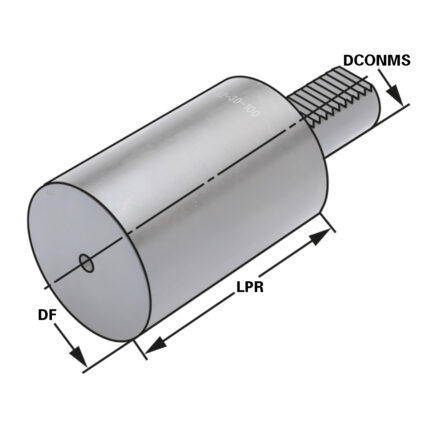

Combi shell mill holder SK 50 – 16 – 55

Application:

For mounting milling cutters with transverse or longitudinal groove.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

ER-Precision collet | stainless steel ER20 | 428ESP | < 5 µm | O 7,5 - 7,0

Micrometer | digital | 125 – 150 with data output | IP 65

Pull studs ~ISO 7388-3 | Form UD | M16 | with drill through | incl. O-ring

Hohen-Einstellgerat elektronisch (mit Magnet)

Application:

To determine position of workpiece surfaces or workpiece lengths in Z-direction on lathes or milling machines.

Note:

The apparatus is placed on the workpiece. With the spindle, now move carefully to the device. As soon as the LED lights up, you have achieved the reference value 50 mm. A safety spring way of approx. 3 mm to cross 50 mm is integrated.

Delivery:

2x SR44W batteries

FREE CONSULTATION