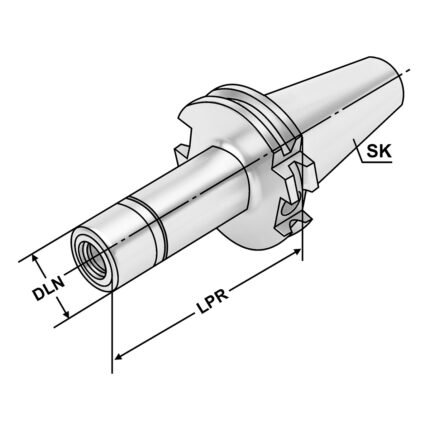

KPS-Collet chuck SK 40 – 4/16 – 60 | KPS 16

Application:

For mounting straight-shank tools in collets. To use for high speed cutting and high precision milling.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

OZ-Precision collet OZ25 | 462EP | < 5µm | O 25 - 24,5

Claw jaws set (Pair) for AVQ-200 | AVL-200 | ALQ-200 | AOM-200

Version:

Jaws with grip serrations und fine step for workpieces with max. edge radius 1 mm, clamping depth 2 mm

- For use on vises

- Simple, safe clamping of parallel raw and sawn parts

- Hydraulic or manual clamping

- Positive clamping due to penetration of the hardened claw tips

- High holding forces: increase by a factor of 3 to 5 compared to standard jaws

- Low material loss

- Shortened processing times and reduction of production and unit costs

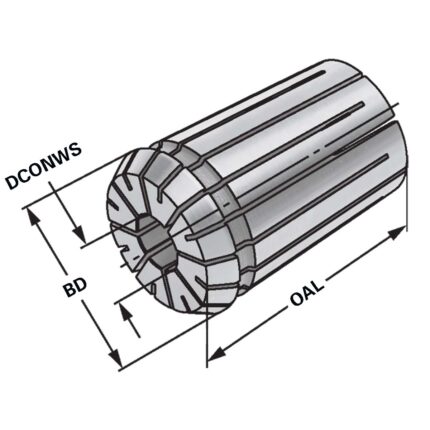

ER-Precision collet | stainless steel ER32 | 470ESP | < 5 µm | O 15,5 - 15

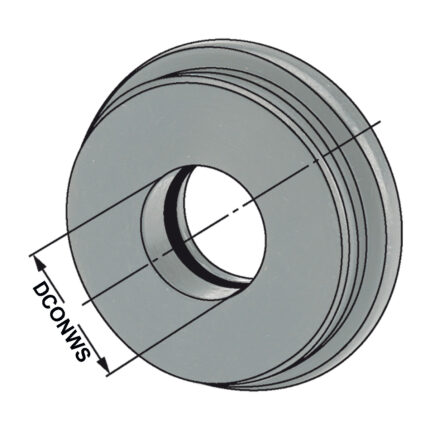

Sealing disc | ER 16 DCONWS = 3,5

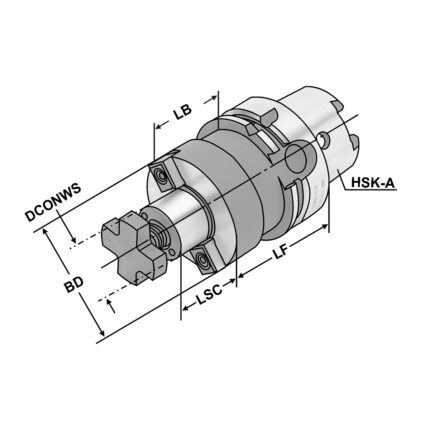

Shell mill holder HSK 63 – 27 – 60

Application:

For mounting milling cutters with transversal groove.

Note:

d = 40/d = 60: For large diameter face mill cutters with four additional threaded holes according to DIN 2079.

SK 30 without coolant exit bores on the end face

Delivery:

With drivers, cross head retaining screw and cylinder head retaining screw for cutters with central coolant. For d = 60 only with four fi xation screws according to DIN 912.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

ER-Collet chuck SK 30 – 3/26 – 60 | ER 40

Application:

For mounting straight-shank tools for woodworking in collets.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined