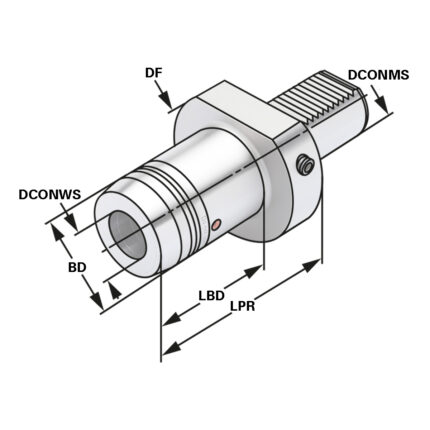

Combi shell mill holder BT 50 – 22 – 160

Application:

For mounting milling cutters with transverse or longitudinal groove.

Delivery:

With retaining screw, driving ring and feather key

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Hydraulic expansion chuck 30 – 20 – 89

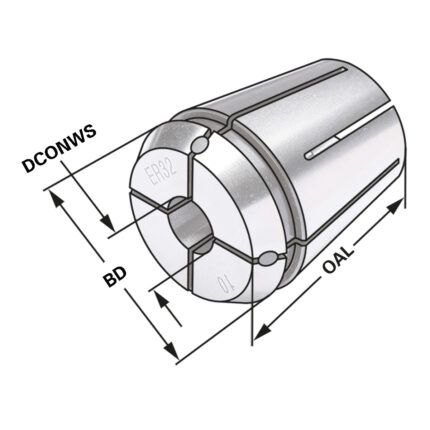

ER-Collet with seal for IC ER32 | 470EA | < 15µm | O 8

Application:

Collets sealed with seal for IC DIN 6499 B (ISO 15488 B) ER-system

Note:

Only nominal size d can be clamped with sealing plug for internal cooling (applicable up to 21 bar) In order to achieve an optimum sealing the tool must be clamped on the complete length of the ground drill of the collet.

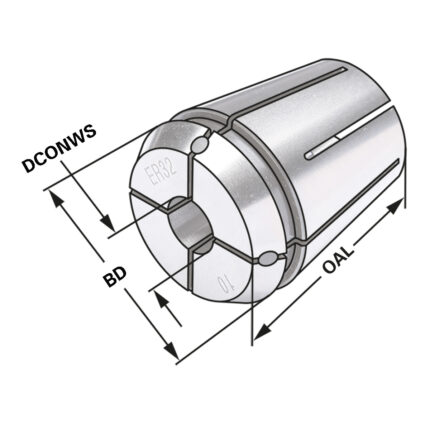

ER-Collet with seal for IC ER25 | 430EA | < 15µm | O 4

Application:

Collets sealed with seal for IC DIN 6499 B (ISO 15488 B) ER-system

Note:

Only nominal size d can be clamped with sealing plug for internal cooling (applicable up to 21 bar) In order to achieve an optimum sealing the tool must be clamped on the complete length of the ground drill of the collet.

End mill cutter 90° 30mm – 25mm Shank after DIN 1835B

HSS-E spiral flute taps fine thread M8 6×4,9 P=0,75 DIN 374

Application:

- Thread configuration with a special design, prevents over-feeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

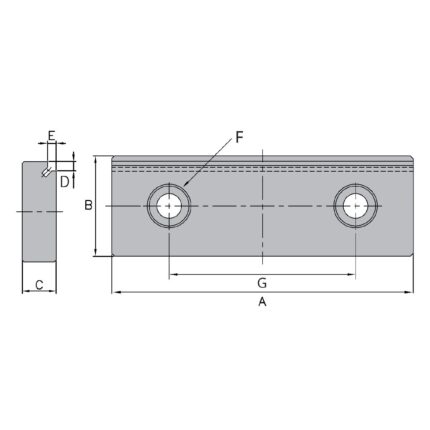

End mill holder Weldon HSK 63 – 20 – 80

Application:

For mounting straight-shank tools with lateral flat according to DIN 1835 form B (Weldon).

Delivery:

With clamping screw

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined