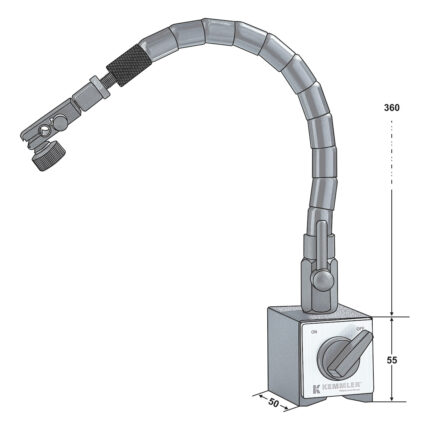

Magnetic base with flexible arm | 360mm | Magnetic power 80kg | O8mm

Sealing disc | OZ 32 DCONWS = 18,5

Collets set | 5 µm | ER16 | stainless steel 426 ESP |

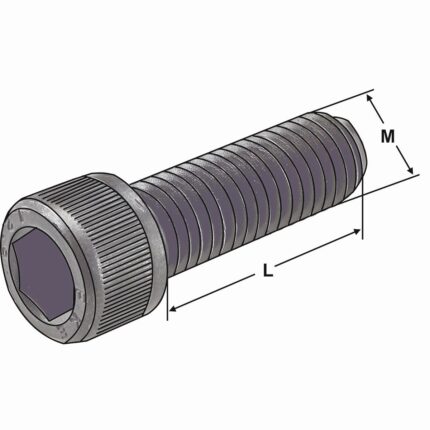

Pull studs ISO 7388-3 | Form JF | M12 | 60° | sealed | without O-ring

Axial toolholder – form C3 overhead right C3 – 40 x 25

Application:

Mainly for external machining. For face machining.

Precision coolant supply: Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.With high precision coolant you get improved

chip breaking, longer tool life, better process security and productivity. Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.

Shrink chuck 4,5° with cooling channels HSK 100 – 12 – 120

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined