PART OF CATALOG

Blade Micrometer | digital | 50 – 75 IP65

Construction:

- Resolution: .00005" / 0.001mm

- For measuring the groove diameter of shafts, keyways, and other hard to reach portions

- Automatic On/Off to maximize battery life

- Upon switching on the display will read the actual absolute measuring position

- Inch/Metric conversion

- Carbide tipped measuring faces

- Non-rotating spindle

- Ratchet stop

Delivery:

- S-wrench

- Standard (over 25mm range)

- Warranty card

- Instruction manual

- Calibration certificate

- LR44 1,5V Battery

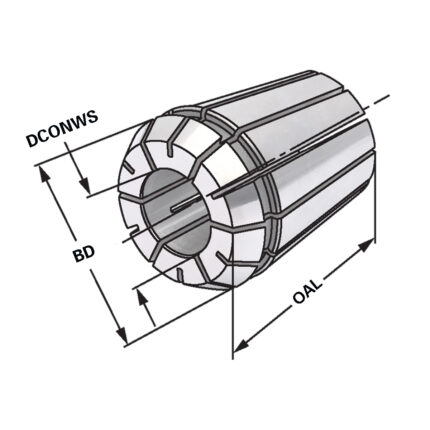

ER-Precision collet ER20 | 428EP | < 5µm | O 4 - 3

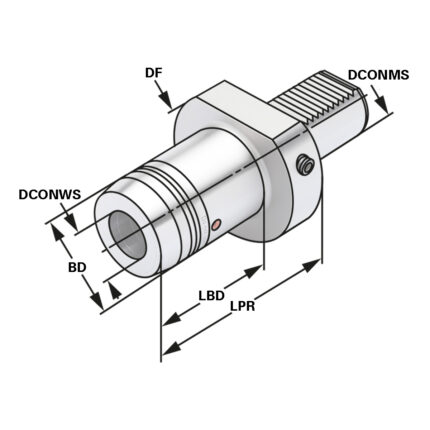

Hydraulic expansion chuck 30 – 20 – 89

Universal assembly block HSK 32

FREE CONSULTATION