Tapping chucks for synchronisation HSK 63 – M3-M12 – 93 | ER 16

Application:

For machining centres with synchronous spindle.

Note:

- Synchro tapping chucks compensate synchronisation errors.

- Minimal length compensation on compression and expansion balances very small pitch differences between synchro spindle and tap, which can cause high frictional forces on the thread flanks.

- A possible increase of axial force during the tapping process is reduced to a minimum.

- Suitable for internal coolant.

- Coolant pressure up to max. 100 bar.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Axial toolholder – form C2 left C2 – 30 x 20

Application:

Mainly for external machining. For face machining.

Precision coolant supply: Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.With high precision coolant you get improved

chip breaking, longer tool life, better process security and productivity. Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.

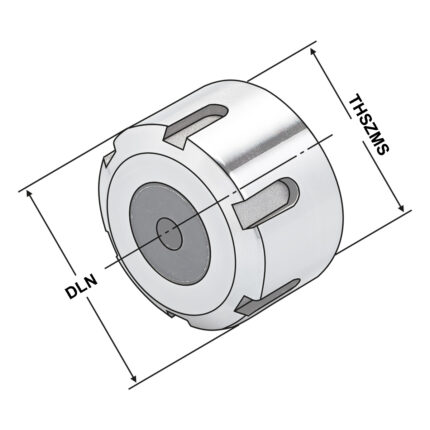

OZ-Precision collet OZ32 | 467EP | < 5µm | O 23 - 22,5

Quick change adaptors with safety clutch Size 1 | M10 | 7 x 5,5 | DIN 376

Adaptor SK to ISO 26623 (PSK) SK 40 – PSK 40 – 40

Application:

For adaption from SK/ISO to PSC (ISO 7388-1 to ISO 26623-1)

Delivery:

Clamping screw

Version:

Adapters HSK / PSK with axial clamping. Ground internally and externally. The internal thread provided for the coolant tube in the PSC toolholder is plugged with the socket-head screw incorporated in the adapter. The clamping screw incorporates a through hole, so the system is suitable for through-coolant feed.

Suitable for tool arbor with polygonal shank (PSC) - ISO 26623-1.

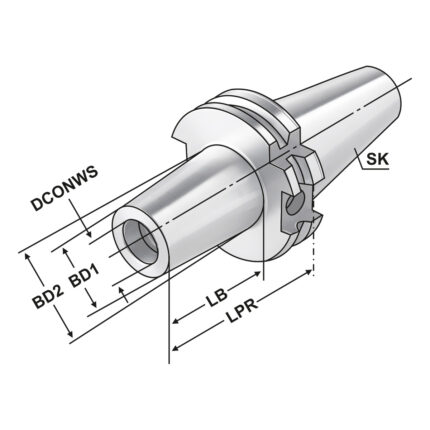

Milling arbors for screw-in cutters SK 40 – M16 – 24 – LB5

Application:

For mounting screw-in cutters with thread.

Delivery:

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined