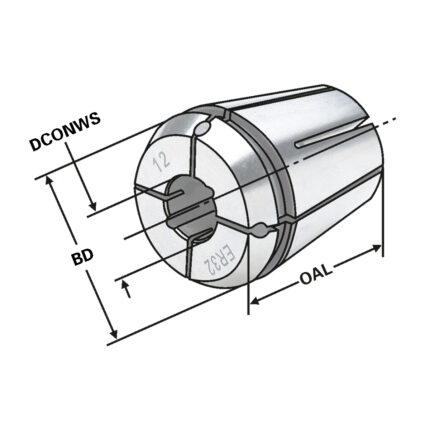

ER-Precision collet ER11 | 4008EP | < 5µm | O 2,5 - 2,0

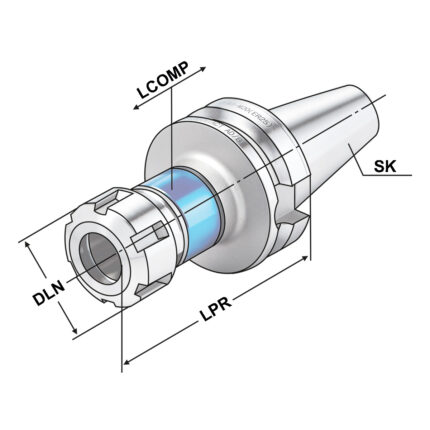

Combi shell mill holder SK 40 – 40 – 60

Application:

For mounting milling cutters with transverse or longitudinal groove.

Delivery:

With retaining screw, driving ring and feather key

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

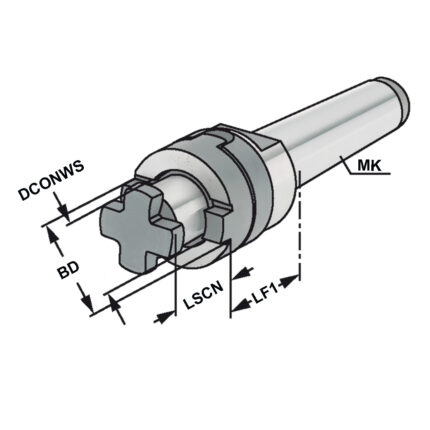

Tapping chucks for synchronisation BT 40 – M3-M12 – 81 | ER 16

Application:

For machining centres with synchronous spindle.

Note:

Synchro tapping chucks compensate synchronisation errors.Minimal length compensation on compression and expansion balances very small pitch differences between synchro spindle and tap, which can cause high frictional forces on the thread flanks.A possible increase of axial force during the tapping process is reduced to a minimum.Suitable for internal coolant.Coolant pressure up to max. 100 bar.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

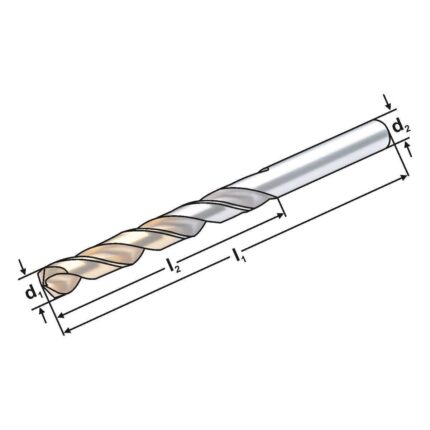

HSSE twist drill 135° 9,1 mm DIN 338 | TIN coating

Combi shell mill holder MK 3 – 22 – 48

HSSE twist drill 135° 10,4 mm DIN 338 | TIN coating

ER-Spannzange mit Kuhlkanalen ER40 | 472ECC | < 15µm | O 16

Hydraulic expansion chuck HSK 63 – 16 – 150

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Delivery:

Without wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined