PART OF CATALOG

Drill chuck adaptor DIN 238 SK 40 – B 18

Application:

For mounting drill chucks.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Ring gauge | 75mm ring gauge-accuracy DIN 2250

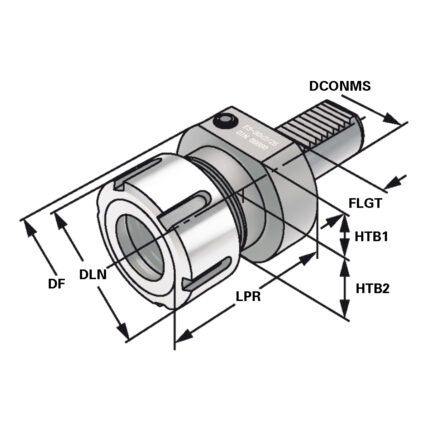

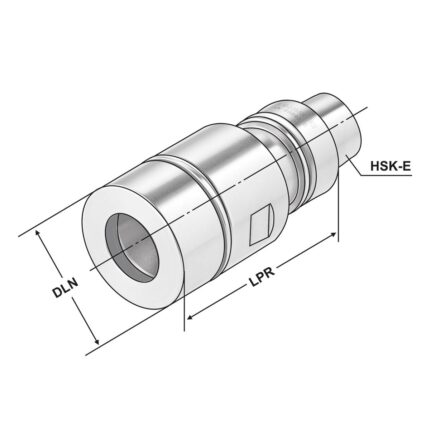

ER-Precision collet chuck HSK 50 – 2/20 – 70 | ER 32

Application:

For mounting straight-shank tools in 2 µm-collets.

Advantage:

- Excellent concentricity in the system (chuck + collet + clamping nut)

- 3 µm radial run-out with a 2 µm clamping nut, 6 µm radial run-out with a 5 µm clamping nut

- Extremely strong holding force (increases the holding power by at least 60% compared to standard ER chuck)

- Plain clamping nut without grooves for high speed machining

Morse taper adaptor SK 30 – 1 – 50

Application:

For mounting tools with Morse taper shank and tang according to DIN 228-1 form B.

Delivery:

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

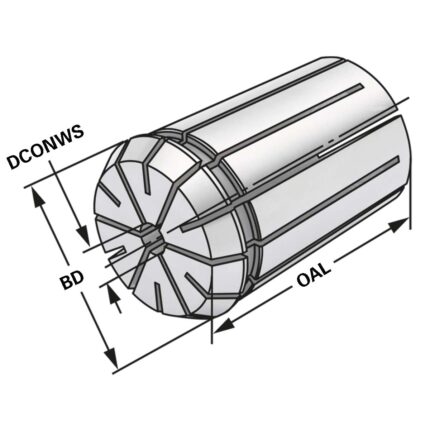

OZ-Precision collet OZ16 | 415EP | < 5µm | O 14 - 13,5

FREE CONSULTATION