PART OF CATALOG

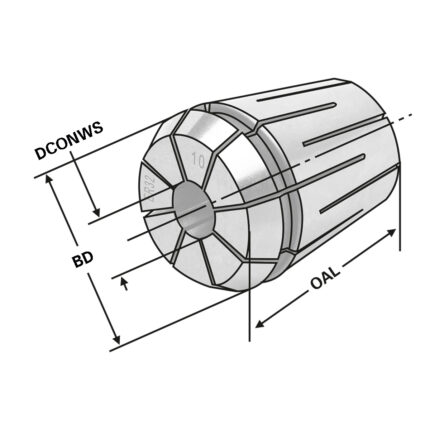

ER-Precision collet | stainless steel ER20 | 428ESP | < 5 µm | O 8,5 - 8,0

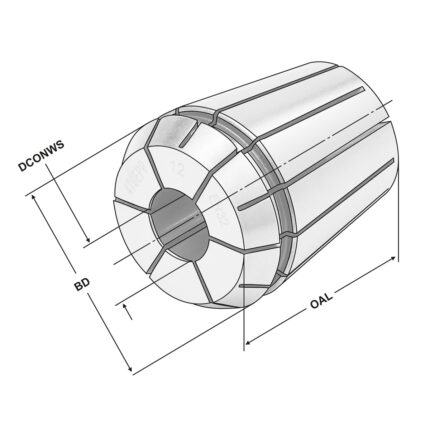

ER-Precision collet ER32 | 470EPP | < 3 µm | O 3,0

Collets - Precision - 3 µm, 470 E (ER 32) - Precision - 3 µm, Collets system ER - Precision - 3 µm, Collets

Application:

For mounting straight-shank tools in collet chucks ISO 15488 (ex. DIN 6499).

Version:

System concentricity and repetition accuracy 3 µm (3?D, maximum = 50 mm), in conjunction with KEMMLER Precision collet chuck ER".

Suitable for:

KEMMLER Precision collet chuck ER or standard collet chuck Spannfutter ISO 15488 (ex. DIN 6499).

Note:

The collet clamping O range is always up to 0.5 mm less than nominal.

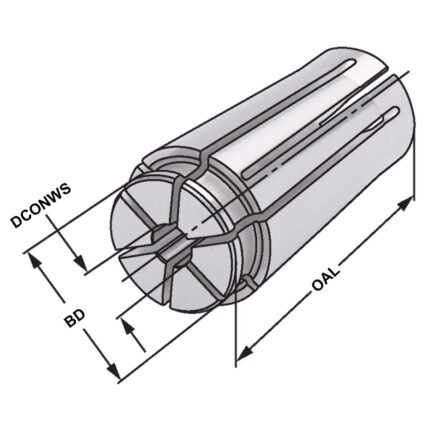

KPS-Prazisionsspannzange abgedichtet KPS 16 | < 5µm | O 10,0

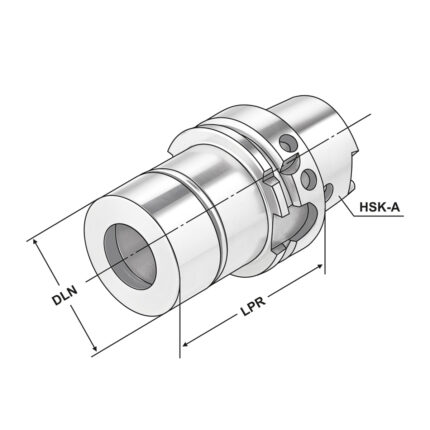

ER-Precision collet chuck HSK 63 – 2/20 – 150 | ER 32

Application:

For mounting straight-shank tools in 2 µm-collets.

Advantage:

- Excellent concentricity in the system (chuck + collet + clamping nut)

- 3 µm radial run-out with a 2 µm clamping nut, 6 µm radial run-out with a 5 µm clamping nut

- Extremely strong holding force (increases the holding power by at least 60% compared to standard ER chuck)

- Plain clamping nut without grooves for high speed machining

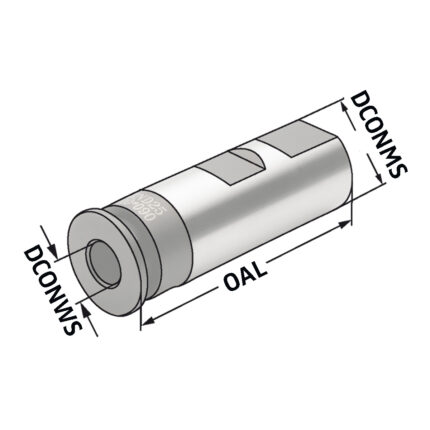

Clamping sleeves for taps with quick change DCONMS=32 | 12 x 9

ER-Collet with cooling channel holes ER16 | 426EC | < 15µm | O 4

FREE CONSULTATION