PART OF CATALOG

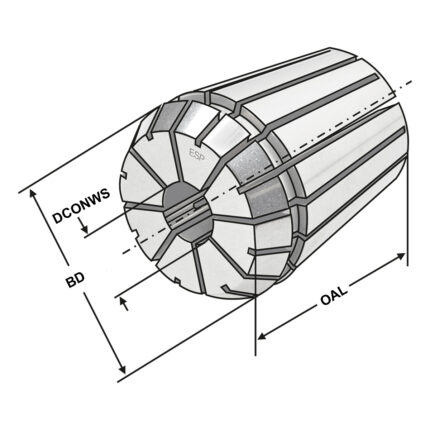

ER-Precision collet | stainless steel ER25 | 430ESP | < 5 µm | O 10,5 - 10,0

KPS-Collet chuck HSK 63 – 1/10 – 105 | KPS 10

Application:

For mounting straight-shank tools in collets. To use for high speed cutting and high precision milling.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Blade Micrometer | digital | 0 – 25 IP65

Construction:

- Resolution: .00005" / 0.001mm

- For measuring the groove diameter of shafts, keyways, and other hard to reach portions

- Automatic On/Off to maximize battery life

- Upon switching on the display will read the actual absolute measuring position

- Inch/Metric conversion

- Carbide tipped measuring faces

- Non-rotating spindle

- Ratchet stop

Delivery:

- S-wrench

- Standard (over 25mm range)

- Warranty card

- Instruction manual

- Calibration certificate

- LR44 1,5V Battery

FREE CONSULTATION