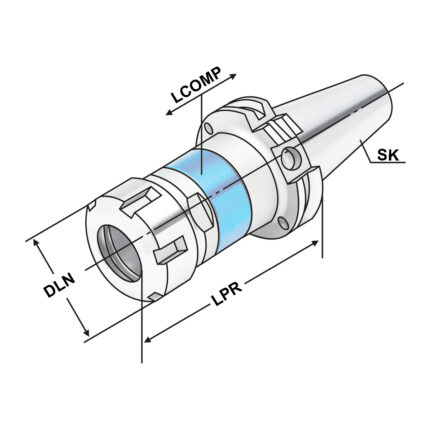

Shrink chuck 4,5° BT 40 – 04 – 80

Application:

For mounting tools with straight shanks.

Note:

Toolholders suitable for induction-, contact- and hot air shrink units. O 3, 4, 5 with h4-tolerance and O 6 O 32 with h6-tolerance

For O 3, 4 and 5 mm only solid carbide tool shanks must be used!

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Claw jaws set (Pair) for AVQ-160 | AVL-160 | ALQ-160 |

Version:

Jaws with grip serrations und fine step for workpieces with max. edge radius 1 mm, clamping depth 2 mm

- For use on vises

- Simple, safe clamping of parallel raw and sawn parts

- Hydraulic or manual clamping

- Positive clamping due to penetration of the hardened claw tips

- High holding forces: increase by a factor of 3 to 5 compared to standard jaws

- Low material loss

- Shortened processing times and reduction of production and unit costs

Tapping chucks for synchronisation SK 40 – M3-M12 – 79 | ER 16

Application:

For machining centres with synchronous spindle.

Note:

- Synchro tapping chucks compensate synchronisation errors.

- Minimal length compensation on compression and expansion balances very small pitch differences between synchro spindle and tap, which can cause high frictional forces on the thread flanks.

- A possible increase of axial force during the tapping process is reduced to a minimum.

- Suitable for internal coolant.

- Coolant pressure up to max. 100 bar.

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Solid carbide NC spot drill 4mm 120°

Version:

Exactly central ground point. Easy spot drilling and high shape accuracy of the centre hole. Sturdy due to short flutes.

Application:

Point angle 120° for spot drilling and countersinking in one operation when a drill of smaller dia. is used afterwards.

Note:

Use the speed for the actual hole dia. (not generally the speed for the drill outer dia.).