PART OF CATALOG

Tapping chucks for synchronisation 32 – M4-M27 | ER 32

Application:

For machining centres with synchronous spindle.

Note:

- Synchro tapping chucks compensate synchronisation errors.

- Minimal length compensation on compression and expansion balances very small pitch differences between synchro spindle and tap, which can cause high frictional forces on the thread flanks.

- A possible increase of axial force during the tapping process is reduced to a minimum.

- Suitable for internal coolant.

- Coolant pressure up to max. 100 bar.

With balanced clamping nut

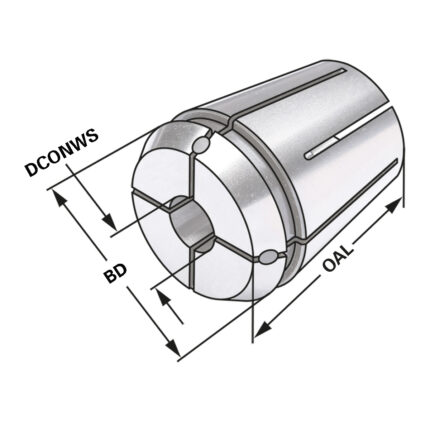

ER-Gewindebohrer-Spannzange IK ER32 | 470GA | < 15µm | 9 x 7

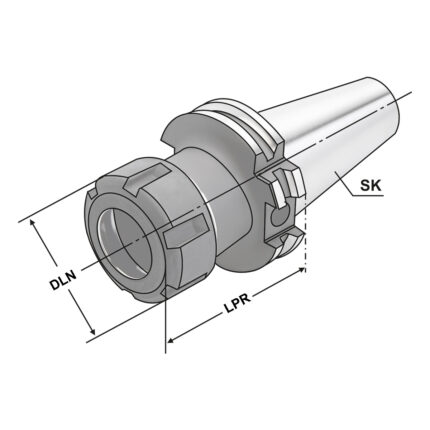

Tapping chucks for synchronisation SK 40 – M3-M20 – 84 | ER 25

Application:

For machining centres with synchronous spindle.

Note:

- Synchro tapping chucks compensate synchronisation errors.

- Minimal length compensation on compression and expansion balances very small pitch differences between synchro spindle and tap, which can cause high frictional forces on the thread flanks.

- A possible increase of axial force during the tapping process is reduced to a minimum.

- Suitable for internal coolant.

- Coolant pressure up to max. 100 bar.

Delivery:

With balanced clamping nut

ER-Collet chuck SK 50 – 2/16 – 60 | ER 25

Application:

For mounting straight-shank tools in collets.

Delivery:

With balanced clamping nut

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Boring holders – form E1 E1 – 20 x 16

Solid carbide ball nose end mill 2 flutes short 14 R7,0 – 14 AlTiCrN coating

FREE CONSULTATION