PART OF CATALOG

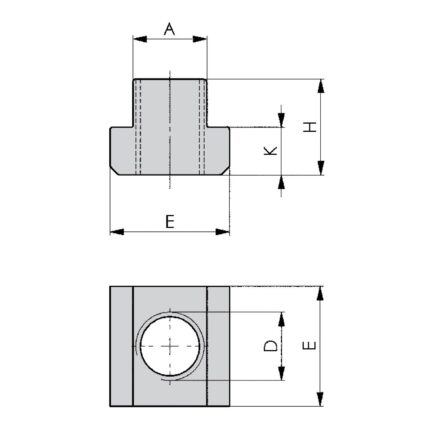

Clamping sleeves for taps with quick change DCONMS=32 | 9 x 7

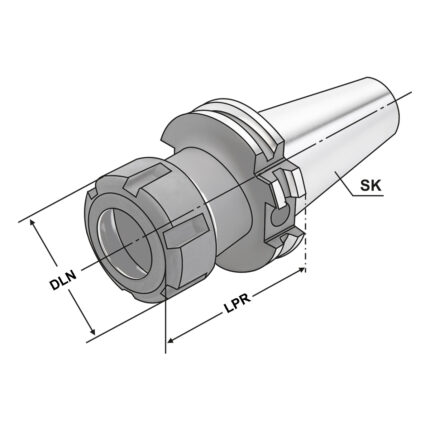

ER-Precision collet chuck HSK 40 – 2/20 – 70 | ER 32

Application:

For mounting straight-shank tools in 2 µm-collets.

Advantage:

- Excellent concentricity in the system (chuck + collet + clamping nut)

- 3 µm radial run-out with a 2 µm clamping nut, 6 µm radial run-out with a 5 µm clamping nut

- Extremely strong holding force (increases the holding power by at least 60% compared to standard ER chuck)

- Plain clamping nut without grooves for high speed machining

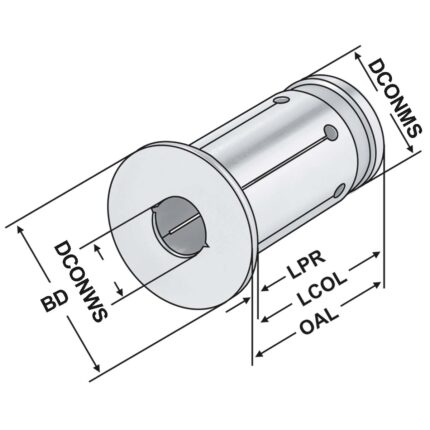

Reduction sleeves for hydraulic expansion chucks DCONMS=20 | DCONWS=6

with coolant channels along the boring, 20mm, Accessories, Accessories for hydraulic chucks, Reducing b. for hydraulic chucks

FREE CONSULTATION