PART OF CATALOG

HSS-E spiral flute taps fine thread M16 12×9 P=1 DIN 374

Application:

- Thread configuration with a special design, prevents over-feeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

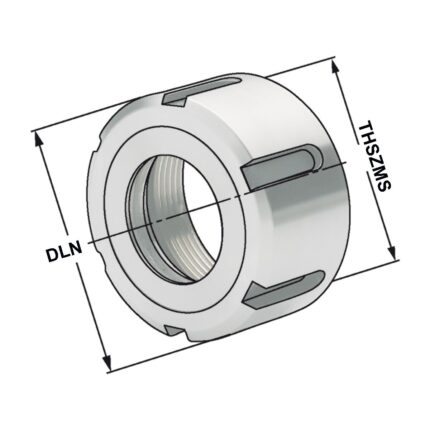

OZ-Collet OZ25 | 462E | < 15µm | O 8 - 7,5

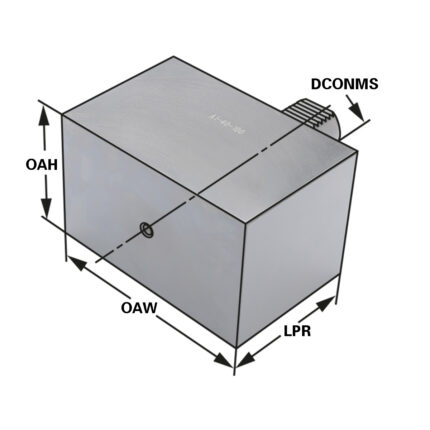

Radial toolholder – form B3 overhead right short B3 – 30 x 20 x 40

Application:

Mainly for external machining. For face machining.

Precision coolant supply: Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.With high precision coolant you get improved

chip breaking, longer tool life, better process security and productivity. Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.

Quick change tapping chuck BT 50 – M3-M14 – Gr.1

Application:

For the chucking of quick change adaptors for taps.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

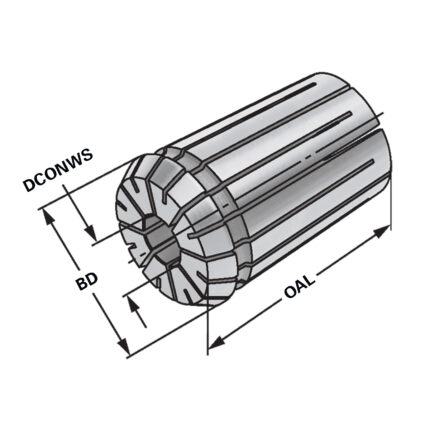

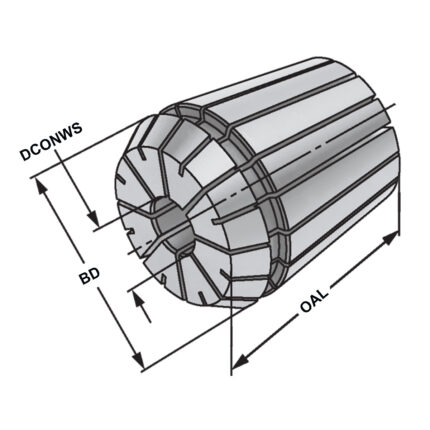

ER-Collet ER 11 | 4008E | < 15µm | O 1,5 - 1,0

FREE CONSULTATION