PART OF CATALOG

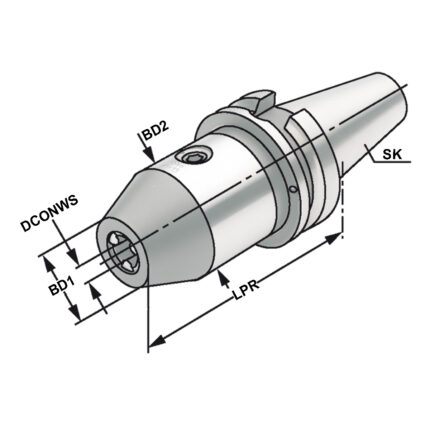

CNC-Drill chuck BT 50 – 1/13 – 108

Application:

For mounting tools with straight shanks.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

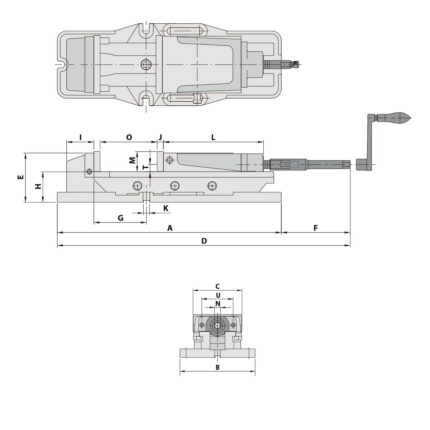

Precision vice MP-80A mechanical with mechanical booster

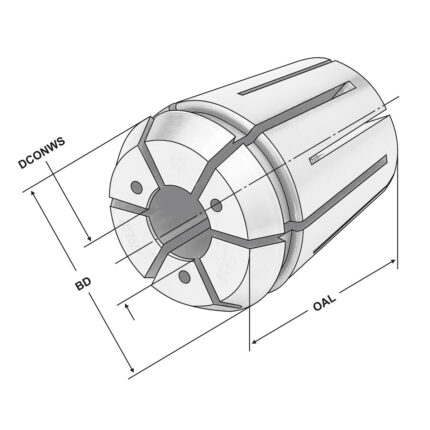

Hydraulic expansion chuck HSK 32 – 08 – 80

Hydraulic expansion chucks, HSK-A 32, New items, Hydraulic chucks special offer 2023, ISO 12164 (HSK-A)

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Delivery:

Without wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

HSSE twist drill 135° 6,6 mm DIN 338 | TIN coating

Plug gauge | 36mm | H7 accuracy DIN 7162|7164 | size DIN 2245

FREE CONSULTATION