PART OF CATALOG

Vierkant-Mehrfach-Aufnahme – form D1 30 – 20 – 60

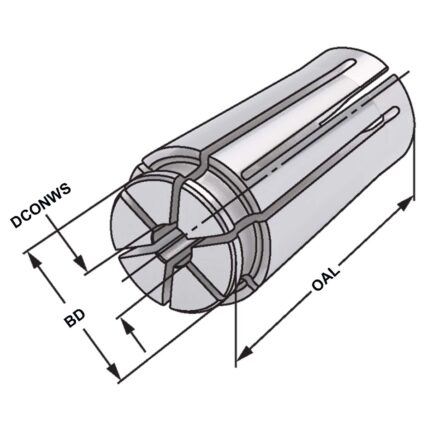

ER-Precision collet chuck HSK 100 – 2/20 – 125 | ER 32

Application:

For mounting straight-shank tools in 2 µm-collets.

Advantage:

- Excellent concentricity in the system (chuck + collet + clamping nut)

- 3 µm radial run-out with a 2 µm clamping nut, 6 µm radial run-out with a 5 µm clamping nut

- Extremely strong holding force (increases the holding power by at least 60% compared to standard ER chuck)

- Plain clamping nut without grooves for high speed machining

Radial toolholder – form B1 right short B1 – 50 x 32 – 55

Application:

Mainly for external machining. For face machining.

Precision coolant supply: Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.With high precision coolant you get improved

chip breaking, longer tool life, better process security and productivity. Improves chip evacuation and decreases the risk for chip jamming, critical factors for successful deep face grooving operations. Effective from low to high coolant pressures.

Screw-in coolant nozzle M6 M6 – 3 – 100

KPS-Prazisionsspannzange KPS 16 | < 5µm | O 14,0-13,5

ER-Precision collet ER11 | 4008EP | < 5µm | O 3,5 - 3,0

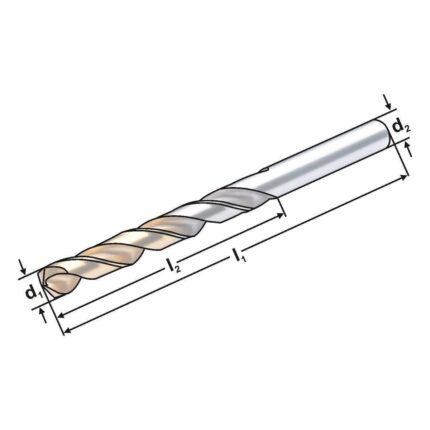

HSSE twist drill 135° 12,7 mm DIN 338 | TIN coating

KPS-Prazisionsspannzange KPS 16 | < 5µm | O 5,5-5,0

FREE CONSULTATION