HSS-E spiral flute taps fine thread M15 11×9 P=1,5 DIN 374

Application:

- Thread configuration with a special design, prevents over-feeding, thin thread and pitch diameter oversize.

- Flute geometry with special design, better chip evacuation, prevents chip clogging, improves thread quality

- Excellent performance on various work material: Stainless steel, carbon steel, alloyed steel, tool steel

Mitlaufende Drehbankspitze | MK 4

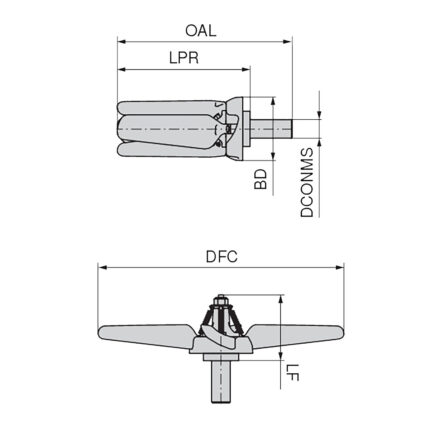

Cleaning propeller | Chip Blower O 16mm – 160mm

Version:

- Robust design

- Opening and closing of the flanks through the spindle speed control

- For use in any tool holder O16mm with a center coolant

- Body made of high strength and anodized aluminum

Advantages:

- Efficient cleaning of clamping equipment, pieces and tables

- Removal of chips und cleaning of water pockets

- Perfekte update to the automated work process

Drehzahlbereich (Empfehlung): Min. 7.000 / Max. 12.000 rpm

Rotationsrichtung: Uhrzeigersinn

Entfernung zwischen geoffneten Flugeln und Spahnen: 100~150 mm

Vorschub (Empfehlung): 1.000~3.000 mm/min

Ideal fur kleine Werkzeugmaschinen mit wenig Spahnen und Kuhlung

Zubehor/Ersatzteil:

Art.Nr.: ERS.900.90.160

Ersatz-Reinigungs-Propeller Typ 160mm

Lieferumfang:

1 Stk. Rotorblatt; Inklusive Feder, Positionier- und Halte-Pin

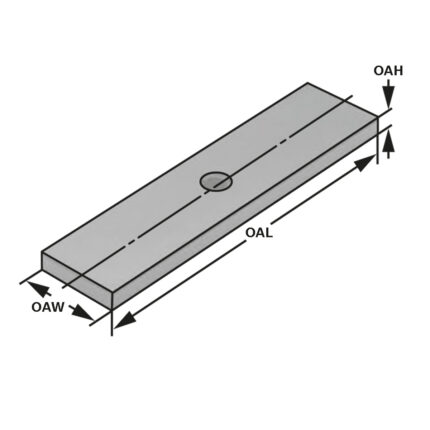

Hydraulic expansion chuck BT 30 – 10 – 64

Application:

For mounting straight-shank tools acc. DIN 1835 form A+B+E and DIN 6535 form HA+HB+HE (larger than dia. 20 mm only with reduction sleeve).

Note:

l1 = max. clamping depth l2 = max. length adjustment range

Delivery:

With wrench

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

End mill holder Whistle-Notch BT 40 – 12 – 63

Application:

For mounting straight-shank tools and inclined flat according to DIN 1835 form E (Whistle Notch).

Delivery:

With clamping screw and axial adjustment bolt

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined