PART OF CATALOG

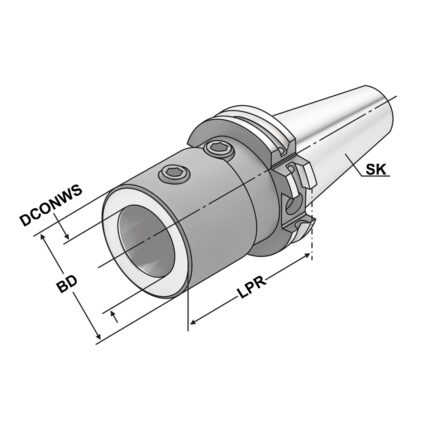

Boring holder for drills with indexable inserts | SK 50 – 32 – 70

Application:

For mounting solid drills with cylindrical shank according to DIN 6595.

Note:

Contact surface precision grinded

Delivery:

With clamping screws

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

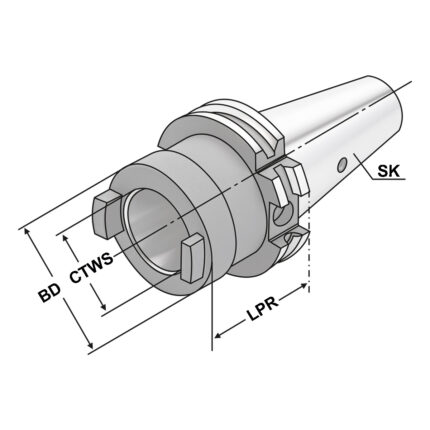

Morse taper adaptor SK 30 – 3 – 75

Application:

For mounting tools with Morse taper shank and tang according to DIN 228-1 form B.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

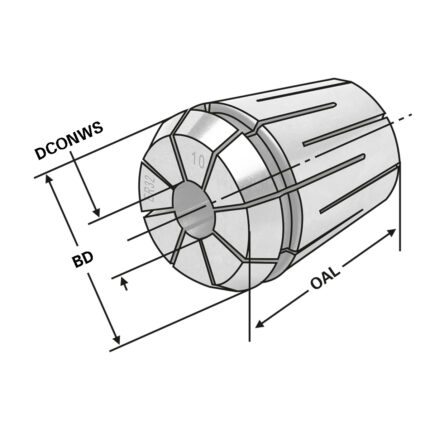

ER-Collet ER16 | 426E | < 15µm | O 2 - 1,5

Adapters SK to SK SK 40 – SK 40 – 100

Application:

For holding tapers according to DIN 69871, JIS B 6339 and DIN 2080.

Delivery:

Delivered with a built-in screw for shortened taper tools. Additional screw for DIN 2080 tools included.

- All holders are made of forged steel

- Specific, low warpage hardened

- Surface hardened HRC 58~60

- Hardening depth 0,8mm~0,9mm

- Taper angle tolerance < AT 3 according to DIN 2080

- Surface roughness Ra < 0,4 µm

- Tensile strength in the core of min. 800 N/mm? after DIN

- All functional surfaces fine machined

Sealing disc | OZ 25 DCONWS = 19,5

Sealing disc | OZ 32 DCONWS = 18,0

FREE CONSULTATION